WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How much copper can be separated from a ton of miscellaneous wires by using copper wire granulator?

June 27, 2023

June 27, 2023- FAQ

- Leave a message

- Chat online

Generally speaking, the copper content of waste miscellaneous wire per ton is about 40%. A copper wire granulator is used for processing waste wire and cable to get pure copper and plastic. The copper separated by the copper wire granulator is about 0.39t from a ton of miscellaneous wires. The market price of copper is around 5699.35/ton, and that of plastic is 556.03/ton, which will fluctuate up and down due to the market situation. If this is taken as an example, the gross profit that can be obtained from a ton of miscellaneous wires is about $3614.22.

Profit ways of copper and plastic

Profit ways of copper and plastic

Actually, the amount of copper that can be separated from a ton of miscellaneous wires by using a copper wire granulator is not fixed. Due to the different types and proportions of waste miscellaneous wires, the copper content in one ton of waste miscellaneous wires is also different. Cause the difference of it is relatively large, you should pay attention to the price and copper content when purchasing scrap miscellaneous wires. A copper wire granulator with a higher separation rate can reduce the loss and separate more copper for profit. Conversely, if the separation rate of the copper wire granulator is low, less copper will be separated from it.

Regarding the amount of copper separated from one ton of waste miscellaneous wires by using a copper wire granulator, I will further analyze its influencing factors next.

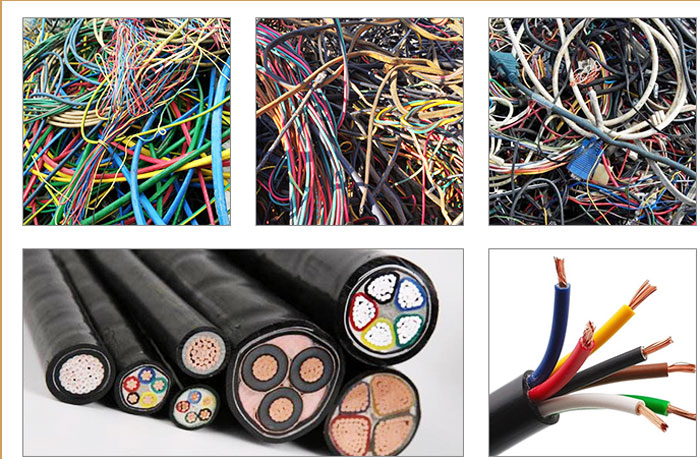

1)The types of miscellaneous wires

Miscellaneous wires contain network cables, copper wires, data wires, square wires, home appliance plug wires, car wires, motorcycle electric lines, computer lines, communication cables, electric wires, household cable wires, and industrial cables, etc.

Miscellaneous wires

Miscellaneous wires

2)The copper content of miscellaneous wires

Here are some data collected for reference. For example, wires disassembled from conventional scrapped cars contain about 53% copper, and wires from scrapped motorcycles contain about 35% copper. The copper content of the car miscellaneous wire is about 48%, the copper content of the network cable is about 40%, the copper content of the square line below 1.5 square meters is about 65%, and the copper content of the square line of 2.5 to 4 square meters is about 62%. The copper content of 6 square meters is about 75%, and the copper content of home appliance plug wires is generally about 25%.

3)The efficiency of the copper wire granulator

There are many types of waste miscellaneous wires, and the structure and material of each type of miscellaneous wire are different, so it is difficult to separate them. Scrap wires are often mixed together, and different types of miscellaneous wires may become entangled or covered by other debris, which increases the difficulty of separation. So the separation of waste miscellaneous wire requires special equipment and technology.

There are two types of copper wire granulators to deal with waste miscellaneous wires, and each of them has pros and cons. The separation rate of physical copper wire granulator is much higher than that of chemical copper wire granulator. What’s more, the copper separated by the physical copper wire granulator is dry, and the price of it is much higher. The fly in the ointment is that the price is slightly expensive. To get more copper for profit and reduce the loss, all things considered, it is recommended to choose a physical copper wire granulator.

Physical copper wire granulator

Physical copper wire granulator

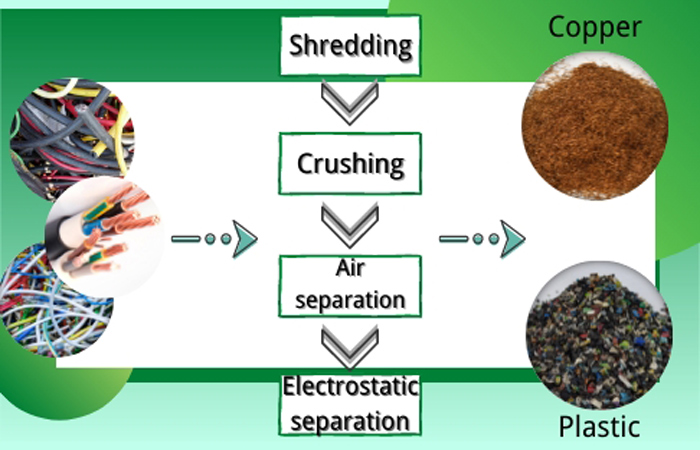

Henan Doing Company specializes in waste recycling machines for more than twelve years and has exported to more than thirty countries. Professional engineers and mature technology make our machines have good performance and environmental protection. Our copper wire granulator is composed of a shredder, crusher, air separator, electrostatic separator, magnetic separator, and pulse dust collector.

Copper wire granulator

Copper wire granulator

The shredder pretreats the miscellaneous wires . The crusher then crushes the pretreated pieces into about 3mm pieces easily in a short time. The crushed material of the crusher is a mixture of copper and plastic, and the next step is to sort. After sorting by the air separator, the separation rate is around 97-98%, and there will be 2-3 points of copper loss. To reduce copper loss, we add an electrostatic separator to the plastic outlet. The electrostatic separation equipment is based on the different charging properties of metals and non-metals, achieving a recovery rate of over 99.9%. A copper wire machine with a relatively high separation rate can improve the recycling efficiency and economic benefits of waste miscellaneous wires.

The working process of copper wire granulator

The working process of copper wire granulator

The configuration ensures that the recycling of each component is completed quickly and accurately. With a PLC control system, the wires and cables granulator is easy to operate by one or two workers. Our machine has different processing capacities for you to choose from, ranging from 200-300kg/h to 1t/h. If you really don’t know how to choose, we have professional engineers and salesmen who can design a suitable scheme according to your requirements.

If you interest in it, and want to know more information about the machine.You can contact us and we will give you our best support.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.