WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

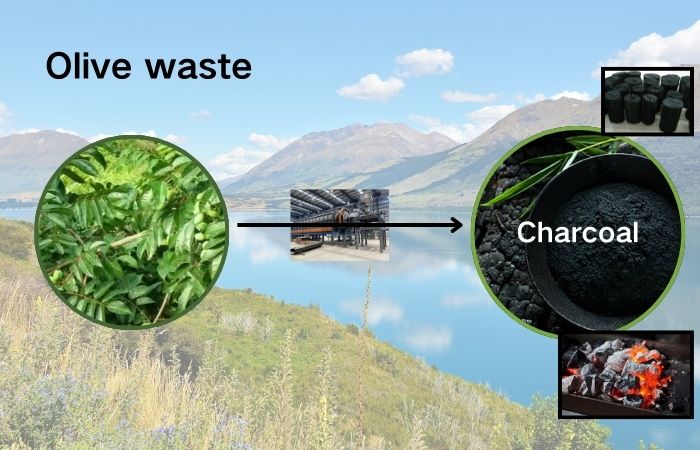

Can olive waste be used to produce charcoal?

November 5, 2024

November 5, 2024- FAQ

- Leave a message

- Chat online

Olives are mainly used to produce olive oil and table olives, and are a common economic plant. The global olive tree planting area exceeds 15 million hectares, of which about 80% are located in the Mediterranean region. Olives are the cornerstone of agricultural economy and sustainable development in these countries. In order to promote the growth of olive trees and produce more high-quality fruits, olive trees in olive plantations need to be pruned every year, so there will be a large number of discarded olive branches and aging olive wood.

Olive waste charcoal production

Olive waste charcoal production

Can these olive wastes be used to produce charcoal? There is no doubt that olive wood is an excellent raw material for the production of charcoal due to its high density and high hardness. These olive woods can be directly burned into natural charcoal through a continuous carbonization furnace. In addition, the production of olive oil produces a large amount of pomace, which can also be made into green olive charcoal through a carbonization furnace. Others such as olivine and olive shells can also be used as raw materials for the production of charcoal. These olive raw materials are inexpensive and easily available in olive-growing areas.

The main application of olive charcoal

Due to its unique physical and chemical properties, olive charcoal has a wide range of applications in many fields. Here are some of the main uses of olive charcoal:

1. Cooking and grilling: Olive charcoal has a stable flame, even heat distribution, and no smoke when burning, making it very suitable for cooking and grilling. It can give food a unique smoky flavor, especially when grilling and making smoked foods.

2. In Chaozhou and other areas of China, olive charcoal is used in the boiling process of Gongfu tea. Because it generates moderate heat when burning, it can help tea leaves fully release their aroma and flavor and improve the quality of tea. At the same time, olive charcoal burns slowly and is resistant to burning, so the price is relatively high.

3. Heating: Olive charcoal has high calorific value and a gentle flame when burning, making it suitable as a fuel for winter heating.

The main application of olive charcoal

The main application of olive charcoal

In addition to the above uses, olive charcoal can also be used to make adsorption materials such as activated carbon, which are used in air purification, water treatment and other fields. In addition, the charcoal ash of olive charcoal can also be used as a fertilizer or soil conditioner for agricultural production.

How to produce olive charcoal from olive waste?

Through the above introduction, we know that olive charcoal has unique advantages in cooking, heating and other aspects. Next, we will introduce how to produce olive charcoal from olive waste.

1. Choose the right equipment

Carbonization furnace is the key equipment for making olive charcoal, which is mainly divided into continuous and intermittent types. If you are a family workshop, intermittent carbonization furnace is more suitable for you. Because the intermittent carbonization furnace is relatively simple to operate and the equipment cost is relatively low. For large-scale, commercial producers, continuous carbonization furnace is more suitable. Continuous carbonization furnace can produce 24 hours uninterruptedly and has high production efficiency. Since it requires certain technical support to ensure stable operation, the equipment cost is also relatively high. But once an efficient production process is established, a large amount of high-quality olive charcoal can be produced quickly, thereby obtaining high profit returns.

Continuous carbonization furnace

Continuous carbonization furnace

2. Principles and steps of making olive charcoal with continuous carbonization furnace

Principle: The continuous olive waste carbonization furnace controls the temperature, oxygen content and other conditions to make the olive waste pyrolyze in a high temperature and oxygen-deficient environment. In this process, the moisture in the olive wood is first evaporated. Then organic matter such as lignin and cellulose gradually decomposes to produce combustible gas and charcoal. The combustible gas can be collected and reused, and olive charcoal is the final product we need.

Production steps: First, the collected olive waste is crushed and dried to facilitate subsequent carbonization and improve the quality of olive charcoal; secondly, the dried olive waste is processed through a high-temperature carbonization furnace to generate charcoal. The gas generated during the carbonization process will be collected and recycled as combustible gas through a condensation system to heat the furnace body and realize the recycling of energy. Finally, the produced olive charcoal can be collected after cooling to a safe temperature.

Continuous carbonization furnace

Continuous carbonization furnace

The above is a complete introduction to the production of olive charcoal from olive waste. As people's awareness of environmental protection and health increases, olive charcoal, as a natural and environmentally friendly fuel and adsorption material, will have a broader application prospect. As a equipment manufacturer with more than ten years of history, Henan DOING Group Co., Ltd. has customized several wood charcoal making projects for customers. If you are interested in our continuous carbonization furnace, please pay attention to our latest news and contact us in advance.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.