WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

What raw materials are suitable for DOING charcoal making machine?

September 10, 2024

September 10, 2024- FAQ

- Leave a message

- Chat online

Charcoal making machines have gained significant popularity in recent years due to their ability to convert various organic waste materials into valuable and eco-friendly charcoal products. These charcoal making machines utilize a process known as pyrolysis, which involves heating the raw materials in the absence of oxygen to break them down into charcoal and other byproducts such as wood vinegar and tar.

The versatility of the raw materials suitable for DOING charcoal making machines is one of their key advantages, allowing users to transform a wide range of organic wastes into profitable resources. Below, we explore some of the most common and suitable raw materials for DOING charcoal making machines.

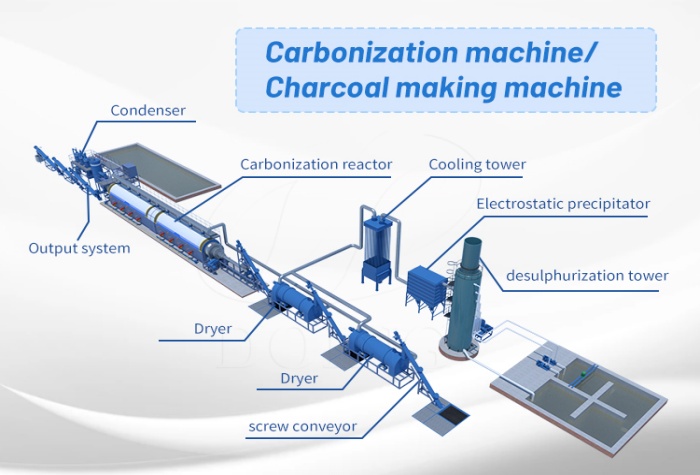

DOING charcoal making machine

DOING charcoal making machine

Agricultural Residues

Agricultural residues are among the most abundant and readily available raw materials for charcoal production. These include:

1. Rice Husk: A byproduct of rice milling, rice husk is often considered waste but contains high amounts of silica, making it an excellent feedstock for charcoal production.

2. Corn Stalks and Cobs: After harvest, corn stalks and cobs are typically left in the fields. However, they can be collected and transformed into high-quality charcoal using DOING charcoal making machines.

3. Sugarcane Bagasse: The fibrous residue left after sugarcane is crushed can be processed into charcoal, providing an additional source of income for sugar mills.

4. Cotton Stalks: Cotton stalks, abundant after cotton harvest, can also be converted into charcoal, reducing waste and promoting sustainability.

Agricultural residues

Agricultural residues

Forestry Waste

Forestry waste includes a variety of materials generated from logging, sawmilling and forest management activities:

1. Wood Chips and Sawdust: These by-products of wood processing are ideal for charcoal production due to their high carbon content.

2. Branches and Twigs: Branches and twigs pruned from landscaping and forestry maintenance can be collected and reused to produce charcoal.

3. Pine Needles: Pine needles are often overlooked, but they can be processed into a unique type of charcoal with unique properties.

Forestry waste

Forestry waste

Municipal Solid Waste (MSW)

DOING charcoal making machines can also handle certain components of municipal solid waste, contributing to reduce waste:

1.Paper and Cardboard: Recycled paper products, if not suitable for further paper production, can be converted into charcoal.

2. Organic Food Waste: Food scraps from homes, restaurants, and markets can be processed, but may require pretreatment to remove moisture and contaminants.

Industrial Waste

Industrial processes generate a variety of waste streams that can be converted into charcoal:

1.Coconut Shells: Coconut shells from the food and beverage industry are a strong material that is ideal for producing high-quality charcoal.

2. Palm Kernel Shells: A byproduct of palm oil production, these shells are another valuable resource for charcoal production.

3. Bamboo: With its rapid growth rate, bamboo is a sustainable resource that can be turned into charcoal for various applications.

Industrial Waste

Industrial Waste

Other Potential Materials

The versatility of DOING charcoal making machines extends to other less conventional materials as well:

1. Animal Manure: When properly processed, animal manure can yield charcoal suitable for soil improvement and fertilization.

2. Tire Derived Fuel (TDF): While not organic, scrap tires can undergo pyrolysis to produce not only charcoal but also fuel oils and steel wires, demonstrating the technology's adaptability.

Choosing the Right Material

Selecting the right raw material depends on several factors, including availability, cost, and intended end-use of the charcoal. Some materials, like hardwoods, may produce a higher quality and more heat-resistant charcoal suitable for barbecuing or industrial applications. Others, such as agricultural residues, might be more accessible and cost-effective but produce lower grades of charcoal suitable for soil amendment or energy generation.

DOING charcoal making machine

DOING charcoal making machine

Besides, it's crucial to preprocess the raw materials to ensure efficient operation and optimal output from the charcoal making machine. This can involve drying the materials to reduce moisture content, shredding or chipping larger items into smaller, uniform pieces, and removing any contaminants like metal or plastic.

Environmental and Economic Benefits

Converting biomass waste into charcoal using the DOING charcoal making machine provides significant environmental benefits by reducing waste volumes, minimizing the need for landfills and reducing greenhouse gas emissions from the decomposition of organic matter. In addition, producing charcoal can create economic opportunities by converting biomass waste into a marketable commodity, promoting circular economy practices and boosting development by adding value to locally available resources.

In conclusion, DOING charcoal making machines are versatile systems capable of transforming a broad spectrum of raw materials into valuable charcoal products. DOING has more than 14 years of experience, focusing on waste recycling machinery. If you are interested in charcoal production business, welcome to consult DOING, we have professionals to serve you one-on-one.

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.