WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

What’s the process of the carbonization machine?

October 24, 2024

October 24, 2024- FAQ

- Leave a message

- Chat online

Coconut shell, peanut shell, palm shell, sawdust, straw, these biomasses can be used as raw materials of carbonization machine to produce finished charcoal. Henan DOING company is committed to providing customers with complete carbonization machine solutions. In order to let you better understand our carbonization machine, the following will briefly introduce its working process.

Carbonization machine

Carbonization machine

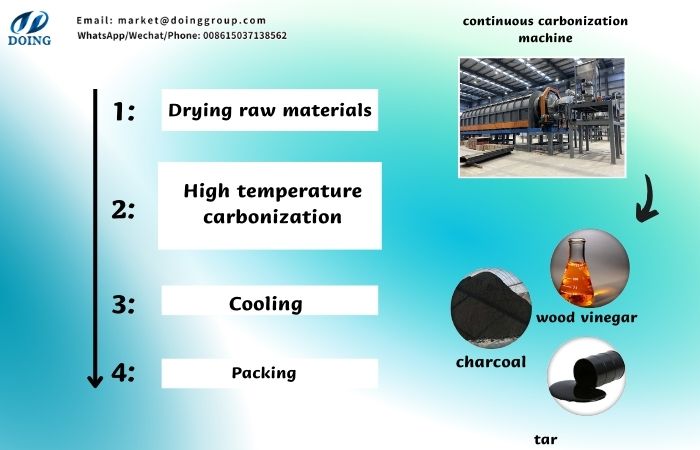

Pretreatment: The continuous carbonization machine needs to pre-treat the size and humidity of the biomass raw materials. DOING continuous carbonization machine provides you with crushing equipment and dryers to help you crush the size of the raw materials and reduce the humidity of the raw materials, to achieve the most efficient carbonization process.

Carbonization: The pretreated raw materials need to be carbonized under high temperature conditions. Temperature control is crucial to the carbonization of raw materials. Too low temperature will lead to carbonization failure. The carbonization machine can control the temperature according to the state of the material, provide a suitable carbonization environment for the raw materials, and ensure that customers produce high-quality finished charcoal.

Continuous carbonization furnace

Continuous carbonization furnace

Packaging: After the charcoal is produced, it needs to be cooled down before packaging, otherwise it will affect the packaging state. The place where the carbonizer discharges charcoal contains a cooling device to help customers reduce the temperature of the finished charcoal and package it in time.

Carbonization machine working process

Carbonization machine working process

Carbonization machine final products:

After above biomass carbonization process, the carbonization machine can not only produce charcoal, but also combustible gas, wood vinegar, tar, etc. These combustible gases can be used as fuel to reheat the carbonization furnace and save energy consumption; wood vinegar contains organic acids, which can be used as a bactericide. Tar can be used as a chemical raw material.

Carbonization machine final products

Carbonization machine final products

The advantage of DOING continuous carbonization machine is that it can achieve 24h uninterrupted production. Carbonized biomass raw materials and finished products move continuously in the furnace, pass through multiple heating and cooling areas, and finally produce carbonized products. In addition, our continuous carbonization machine is also equipped with a flue gas purification system and a PLC control system, which is not only more convenient to operate, but also ensures the safety and environmental protection of the production process.

Henan DOING Company has been engaged in the manufacture of continuous carbonization machine for nearly 14 years. If you want to know more about the technology process and detailed information of DOING continuous carbonization machine, please contact us for consultation!

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.