WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How to realize resource utilization of waste lithium batteries?

October 22, 2024

October 22, 2024- FAQ

- Leave a message

- Chat online

Lithium batteries have become an integral part of our modern world, powering everything from smartphones and laptops to electric vehicles and renewable energy systems. However, as the demand for these batteries continues to rise, so does the amount of waste generated from their end-of-life phase. This presents both a significant environmental challenge and an opportunity for resource recovery and sustainable practices. In this article, we will explore various methods for realizing the resource utilization of waste lithium batteries.

Understanding the Lithium Battery Lifecycle

Before diving into solutions, it is crucial to understand the life cycle of lithium batteries:

Production: Lithium batteries are made using raw materials such as lithium, cobalt, nickel, manganese and graphite.

Use: These batteries power devices until they reach their end of life.

Recycling: After use, lithium batteries can be recycled to recover valuable materials.

Disposal: Proper disposal is essential to prevent environmental pollution.

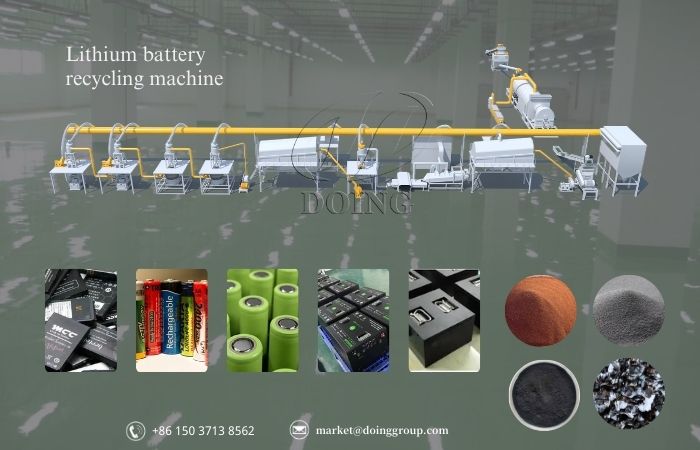

Lithium battery recycling machine

Lithium battery recycling machine

Methods for realizing the resource utilization of waste lithium batteries

Physical separation methods involve treating waste lithium batteries using mechanical or thermal techniques to separate valuable metals and other components. Mechanical recycling involves crushing the lithium batteries into smaller pieces, which are then separated by magnetic, electrostatic or air separator. Thermal techniques involves melting lithium batteries after high-temperature treatment to extract metals such as lithium, cobalt and nickel.

Chemical methods aims to extract specific metals or chemicals from battery waste, mainly including: leaching and precipitation. Leaching refers to dissolving battery materials in solvents to extract valuable metals. Precipitation uses chemical reactions to precipitate metals from solutions into solid compounds for easy extraction.

The physical separation methods produce mixed metals, which is environmentally friendly but has limited sorting; the chemical methods produces high metal purity but has a great impact on the environment and high wastewater treatment costs. In order to achieve high sorting effect and environmental protection, DOING lithium battery recycling machine combines pyrolysis technology with mechanical crushing and physical sorting to efficiently separate black mass, diaphragm, copper and aluminum from waste lithium batteries.

Lithium battery recycling machine

Lithium battery recycling machine

Its working principle is as follows: First, waste lithium batteries are disassembled by a shredder, and then the diaphragm, electrolyte and binder are removed by high-temperature pyrolysis technology. This step is very critical and can effectively separate impurities. Next, precious substances such as copper, aluminum, and black powder are recycled one by one through sophisticated separation technology.

Lithium battery recycling machine

Lithium battery recycling machine

At the same time, our lithium battery recycling machine integrates pulse dust removal and air purification functions, supplemented by PLC control system, which can realize automated processing. This design not only reduces environmental pollution, but also ensures that the entire operation process is more environmentally friendly and efficient.

Henan DOING, an enterprise specializing in the manufacture of waste recycling equipment, has development an efficient and environmentally friendly lithium battery recycling machine, which can extract valuable materials and realize resource utilization of waste lithium batteries. For more details about lithium battery recycling machines, please feel free to contact us, and we can provide corresponding solutions and quotations for your needs.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.