WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How to build a waste circuit board production line with low budget?

August 1, 2023

August 1, 2023- FAQ

- Leave a message

- Chat online

Building a waste circuit board production line with a low budget can be a challenging task. However, with careful planning, it is possible to create an efficient and cost-effective production line. In this passage, we will explore various strategies and considerations to help you achieve this goal.

Firstly, it is essential to choose a proper waste circuit board production line.

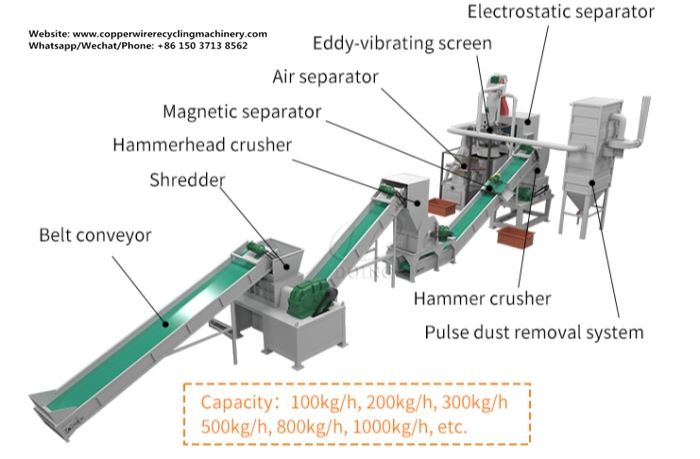

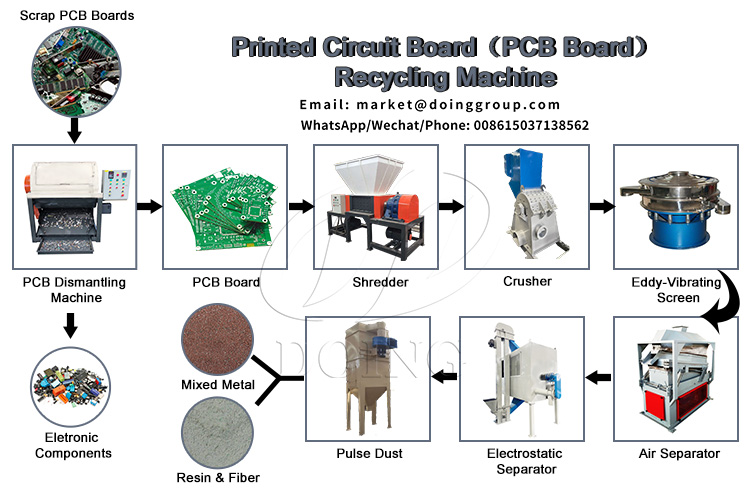

A typical production line consists of several stages, including electronic component dismantling, shredding, crushing and separating. Each stage requires specific equipment and machinery. The waste circuit board production line is usually consist of a shredder, two crushers, an eddy vibrating screen, an air separator and electrostatic separator, a pulse dust collector.

The configuration of waste circuit board production line

The configuration of waste circuit board production line

Choosing a proper waste circuit board production line is not a simple matter, and several factors need to be considered, such as configuration, the separation rate, capacity, raw materials and so on. Generally speaking, the price will be higher due to the complex configuration and large capacity. Let’s use the example of Henan Doing waste circuit board production line to explain. You can see that there are different processing capacities available, and the cost of circuit board recycling machines is vary. If you want to process waste circuit boards with electronic components, you will need to add a PCB dismantling machine.

Waste circuit board production line

Waste circuit board production line

Therefore, it is very complex to choosing a proper configuration for your waste circuit board production line, but Henan Doing can provide you more detail information and help. Henan Doing Company is specialized in waste recycling machine more than twelve years, and we have high qualified engineer team and professional salesmen. We can provide a perfect scheme according to your raw materials and requirements to reduce you consumption and maximized the profits.

To further reduce costs, consider seeking financial assistance or grants from government agencies or non-profit organizations.

Many countries and regions offer funding programs to support sustainable and environmentally friendly initiatives. Research and apply for such programs to help offset the costs of building your waste circuit board production line.

Government agencies or non-profit organizations

Government agencies or non-profit organizations

Lastly, it is crucial to continuously evaluate and improve your waste circuit board production line to optimize efficiency and reduce costs.

Regularly monitor and analyze key performance indicators, such as production output, material consumption, and energy usage. Identify areas for improvement and implement appropriate measures, such as process optimization or equipment upgrades. Additionally, stay updated with the latest advancements in waste circuit board recycling technologies to ensure that your waste circuit board production line remains competitive and efficient.

The details of waste circuit board production line

The details of waste circuit board production line

You can create an efficient and cost-effective waste circuit board production line according to these aspects. By the way, remember to stay informed about the latest technologies and industry trends to remain competitive in this rapidly evolving field.

Waste circuit board can be a valuable source of income if you are willing to put in the effort. Our waste circuit board production line can help you do it more efficiently and with less waste, allowing you to maximize your profits. If you are interested and want to know more details, please contact us.

Contact Us

- Email:

- Tel/WhatsApp:

News

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.