WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

What devices are included in the production line for waste circuit board metal extraction?

July 20, 2023

July 20, 2023- FAQ

- Leave a message

- Chat online

The production line of the waste circuit board recycling machine is a complex system that combines various devices to extract valuable metals from electronic waste. By utilizing these devices, we can recover precious metal resources for reuse or sale, thereby contributing to a sustainable economy and environmental protection.

Waste circuit board recycling machine

Waste circuit board recycling machine

The first step is not imperative for motherboards. But if your waste circuit board has electronic components, it is necessary to add an electronic component dismantling machine, which is a device to remove electronic components from the waste circuit board. When the electronic component dismantling machine rotates after heating by electricity or gas, the circuit boards rub against each other, and the electronic components are separated from the circuit board. The electronic components can be sold indirectly, and the motherboard will be shredded firstly.

Electronic component dismantling machine

Electronic component dismantling machine

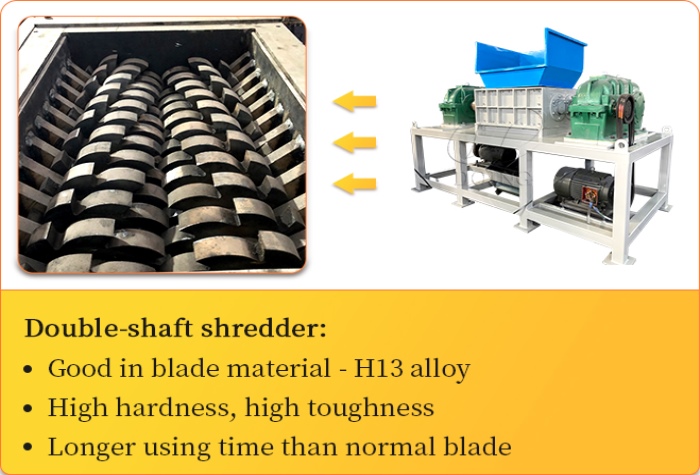

One of the key devices in this waste circuit board metal extracting production line is the shredder. This machine is responsible for breaking down the waste circuit boards into smaller pieces, making it easier for subsequent processes to extract the metals. For better effect, the waste circuit board recycling machine is commonly equipped with a double-shaft shredder.

Shredder

Shredder

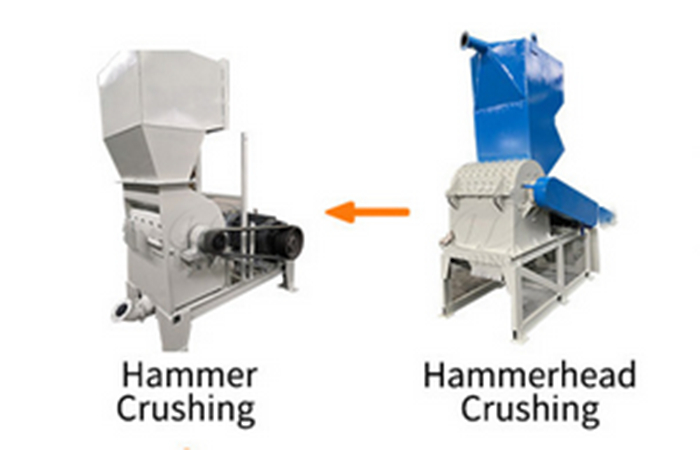

Different from other manufacturers, Henan Doing adopts a double crushing mode, that is, a hammer head crusher and a hammer crusher. This design minimizes wear and maximizes the lifespan of the blade. These crushers utilize sharp blades and hammers to tear apart waste circuit boards, reducing them to a size suitable for further processing.

Crushers

Crushers

Once the circuit boards are crushed, they are fed into an eddy-vibrating screen separator. This device separates the shredded materials based on their size. The smaller particles, which contain a higher concentration of metals, are directed towards the next stage of the production line, while larger particles are sent back to the crusher for further processing. In order to increase the profits of metals separated, most clients will take the initiative to request to add a magnetic separator between these two crushers to remove iron and steel. The ferrous metals are collected, while the non-ferrous metals are directed towards the next stage of the production line.

Eddy vibrating screen

Eddy vibrating screen

The next part in the waste circuit board metal extracting production line is the air separator. This device utilizes air currents to separate the materials based on their gravity. The lighter materials, such as plastic and fiber, are blown away by the air currents, while the heavier materials, including metals, fall into a separate collection bin. This process helps to further concentrate the metals, making their extraction more efficient.

Air separator

Air separator

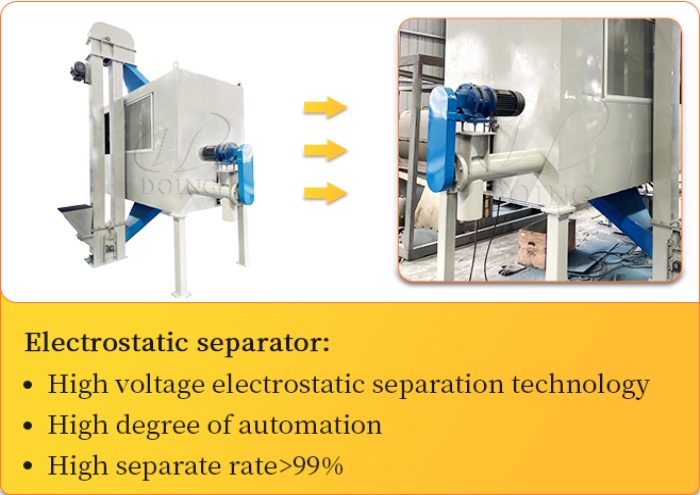

The last part in the waste circuit board metal extracting production line is an electrostatic separator, which uses high voltage electrostatic charges to separate crushed particles of materials by their different charges. The electrostatic separator is widely used in our electronic waste recycling machinery, such as copper wire recycling machines, waste circuit board recycling machines, etc. The separate rate of the electrostatic separator can reach almost 100%.

Electrostatic separator

Electrostatic separator

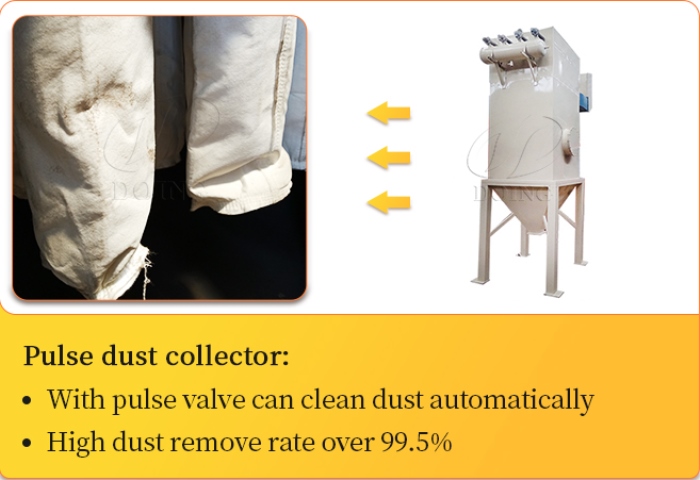

In addition to the above devices, the production line of the waste circuit board recycling machine also includes a dust collector system. This system helps to capture and contain any dust or fine particles generated during the shredding and separation processes. By effectively controlling dust emissions, the waste circuit board metal extracting production line ensures a cleaner and safer working environment.

Pulse dust collector

Pulse dust collector

If you are willing to put in the effort, scrap electronic waste can be a lucrative source of income. DOING waste circuit board metal extracting production lines are tailored to help you accomplish this more efficiently and with minimal waste, enabling you to maximize your profits. If you are interested and would like to know more details, please contact us.

Contact Us

- Email:

- Tel/WhatsApp:

News

What are the characteristics of DOING solar panel recycling machine?

A set of organic waste continuous carbonization equipment was delivered to Vietnam

Photovoltaic panel recycling machine from Henan DOING was shipped to the UK

Good news! British customer ordered photovoltaic panel recycling machine from Henan DOING

New order - Vietnamese customers ordered a carbonization equipment from Henan DOING

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.