WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Domestic waste solution: continuous carbonization pyrolysis furnace

August 22, 2024

August 22, 2024- FAQ

- Leave a message

- Chat online

With the acceleration of urbanization, urban domestic waste treatment has become an urgent environmental issue. In order to seek sustainable solutions, modern society is constantly exploring innovative methods to find a balance between waste management and ecological protection.

Domestic waste

Domestic waste

Innovative solution: continuous pyrolysis carbonization furnace

DOING smokeless continuous carbonization furnace consists of conveyor belt, drying furnace, carbonization furnace, product collection device, dust removal system, automatic control cabinet and other equipment. It is the latest developed continuous carbonization equipment that integrates high efficiency, environmental protection and intelligence.

DOING smokeless continuous carbonization furnace

DOING smokeless continuous carbonization furnace

Charcoal making is a unique method of domestic waste treatment. Charcoal making machine converts organic waste into carbonaceous products under high temperature and low oxygen conditions. During the charcoal making process, organic matter is decomposed into carbonaceous solids, reducing the volume of garbage and producing products that can be used for a variety of purposes such as soil improvement, energy and filter materials.

DOING continuous carbonization pyrolysis furnace can not only effectively treat a large amount of domestic waste, but also provide a way to sustainably utilize resources and reduce dependence on traditional energy.

What raw materials can our carbonization pyrolysis furnace process?

Raw materials

Raw materials

DOING continuous carbonization pyrolysis furnace can process household waste including: fruits and vegetables, leftovers, bones, vegetable roots and leaves and other organic waste. In addition, it can also process peanut shells, sawn wood, corn stalks, bagasse, branches, rice husks, bamboo scraps, sorghum stalks, corn cobs, sorghum stalks, coconut shells, coffee grounds, cotton stalks, bean stalks, dead leaves and other wastes, and make high-quality, environmentally friendly and efficient machine-made charcoal or charcoal powder through high temperature.

How does the continuous carbonization pyrolysis furnace work?

DOING continuous carbonization furnace is a double-furnace structure, divided into an inner tube and an outer tube. The raw materials first enter the inner cylinder of the carbonization furnace. The temperature of the inner cylinder is relatively low. As the main furnace rotates, the materials move horizontally under the action of the guide spiral blades, and then fall into the outer cylinder; the temperature of the outer cylinder is relatively high, and the direction of the spiral is opposite to that of the inner cylinder. The materials move back horizontally, and when the carbonization is completed, they just move to the carbon outlet at the bottom of the carbonization furnace. The charcoal outlet adopts a cooling system to cool the charcoal to room temperature before it is discharged from the furnace.

Products and uses after carbonization of domestic waste

Products and uses

Products and uses

Continuous carbonization pyrolysis furnaces usually use a heating furnace method. Domestic waste is put into the furnace. Under high temperature and oxygen-free or low-oxygen environment, organic matter undergoes carbonization reaction, and is finally converted into a variety of recyclable substances such as charcoal, gas and liquid. The charcoal material produced by the continuous carbonization furnace is clean and non-toxic, has high thermal energy, good market sales and broad prospects.

The products after carbonization have the characteristics of high fixed carbon content, high calorific value, and low volatility, and can be used in power generation, heating, fertilizer production and other fields. At the same time, liquid oil and gas can also be obtained through pyrolysis, which can be used to produce lubricants, fuels, etc., with high economic value.

Advantages of continuous carbonization pyrolysis furnace

1. It realizes continuous feeding, continuous carbonization, continuous carbonization and other production processes, improves production efficiency, and solves a large number of domestic waste disposal problems.

2. Intelligent control: The equipment adopts an intelligent control system to save labor.

3. Low-carbon and environmentally friendly: flammable, smokeless, no charcoal head, and no sparks when burning. No trees are cut down, and organic waste is used for production, turning waste into treasure.

4. High efficiency and energy saving: This equipment realizes high-temperature, continuous, and multi-layer carbonization technology, fully realizing the advantages of high efficiency and energy saving.

5. By-product collection: During the carbonization process, tar, wood vinegar and combustible gas can be automatically collected, realizing the efficient and comprehensive utilization of renewable energy.

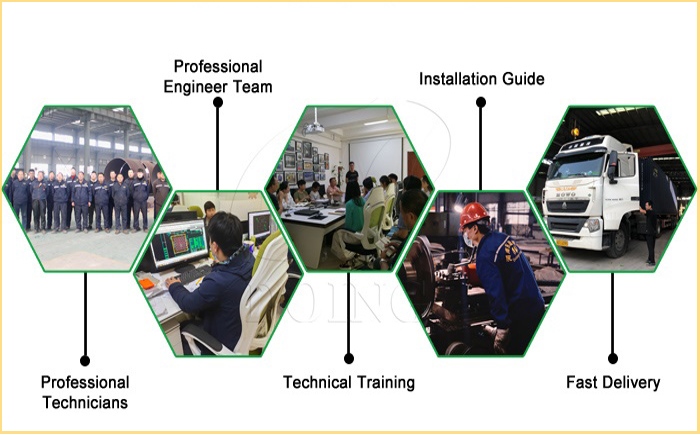

Our service

Our service

Continuous carbonization pyrolysis furnace has broad application prospects in the field of domestic waste treatment. It can make domestic waste a resource and harmless, and at the same time reduce the amount of landfill and reduce pollution to the environment. To learn more about DOING continuous carbonization pyrolysis furnace, please pay attention to our website or contact us.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.