WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How to set up a charcoal making plant?

July 30, 2024

July 30, 2024- FAQ

- Leave a message

- Chat online

Setting up a charcoal making plant involves several key steps, from obtaining the necessary resources and equipment to ensuring safety and environmental compliance. This process requires careful planning and adherence to local regulations to ensure a successful and sustainable operation.

Step 1: Market Research and Feasibility Study

Before investing in a charcoal making plant, conduct a thorough market research to understand the demand for charcoal in your area, identify potential customers and evaluate competitors and their products (including price and quality).

Raw materials and products

Raw materials and products

Conduct a feasibility study to evaluate the technical, financial and operational aspects of the project. This includes estimating the cost of raw materials, equipment, labor and energy. Also, consider the market size, growth potential and profitability projections within a specific time frame.

Step 2: Choose the Right Location

Select a location that has adequate infrastructure (roads, power supply, water), and complies with zoning laws and regulations. Opt for a site that minimizes transportation costs and environmental impacts.

Step 3: Obtain Necessary Permits and Licenses

Obtain all necessary permits and licenses from local government authorities, which may include environmental impact assessments, zoning approvals, and business registrations to ensure compliance with health, safety, and environmental standards.

Step 4: Equipment Selection and Purchase

There are many types of charcoal making machines on the market. Each equipment has its own advantages and disadvantages and applicable scenarios. When selecting charcoal making machine, you need to consider the production needs of the equipment, initial purchase cost, installation costs, operating costs (such as electricity, fuel, etc.) and possible maintenance costs. If conditions permit, it is best to visit the manufacturer of the charcoal making machine on site and select a supplier with good market reputation and customer reviews to reduce possible problems and risks in the later stage.

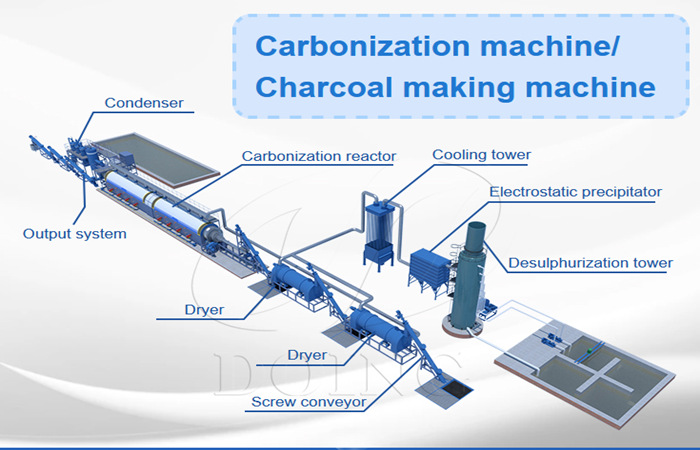

Charcoal making machine

Charcoal making machine

As a professional charcoal making machine manufacturer, DOING provides an efficient and environmentally friendly method of converting biomass waste into charcoal. DOING charcoal making machine is a continuous carbonization machine that can efficiently convert biomass materials into high-quality charcoal, wood vinegar, tar and waste gas through high-temperature pyrolysis technology. By adopting the continuous operation mode, energy consumption is significantly reduced and the production cycle is shortened, thereby improving production efficiency.

Step 5: Raw Material Sourcing

Establish reliable sources for biomass waste, which can be agricultural waste (straw, sawdust, rice husks, corn cob, coconut shell), wood chips, bamboo, or other organic materials. Ensure a steady supply chain to avoid disruptions in production.

Raw materials

Raw materials

Step 6: Environmental Compliance

DOING charcoal making machine is usually equipped with exhaust gas treatment and recycling systems, which can effectively reduce the emission of carbon dioxide and other pollutants generated during the production process. Besides, DOING charcoal making machine incorporates an advanced PLC control system to realize comprehensive automated control and monitoring of the production process. This not only ensures the reliability and stability of the production process and product quality, but also greatly reduces the burden of manual intervention.

DOING can provide complete services according to your needs from plan formulation, equipment configuration, charcoal making machine supply and installation. If you want to know more details, please feel free to contact us.

Contact Us

- Email:

- Tel/WhatsApp:

News

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.