WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How many tons of raw materials produce one ton of charcoal?

April 11, 2024

April 11, 2024- FAQ

- Leave a message

- Chat online

The amount of raw materials used to produce one ton of charcoal is a concern of most investors. It is closely related to the investor's investment cost, production scale and final profit. In this article we will explore how many tons of raw materials are required to produce one ton of charcoal?

Generally speaking, 70% to 80% of raw materials are consumed in the production process of charcoal, while the remaining 20% to 30% of raw materials will be converted into by-products such as wood vinegar, tar and gas. In other words, approximately 3.5 tons to 5 tons of raw materials are required to produce one ton of charcoal.

Raw material and charcoal

Raw material and charcoal

The amount of raw material required to produce one ton of charcoal can vary depending on factors such as the type of raw material, its moisture content, the efficiency of the production process and the desired quality of charcoal. Let’s specifically analyze these factors one by one.

1.Type of raw material:

The raw materials for making charcoal are very rich, including: wood, sawdust, rice husks, coconut shells, bamboo, branches and various hardwoods, nut shells, etc. However, as a general guideline, the ratio of raw material to produced charcoal is typically in the range of 3:1 to 6:1, meaning that 3 to 6 tons of raw material are required to produce 1 ton of charcoal. This ratio is based on the significant weight loss that occurs during pyrolysis, which is the thermal decomposition of organic matter in the absence of oxygen.

Raw materials

Raw materials

For raw materials such as wood chips and branches, it usually takes 3-3.5 tons of raw materials to produce one ton of finished charcoal, while for lighter raw materials such as straw and rice husk, it usually takes about 4 tons of raw materials to produce one ton of charcoal. The specific amount of raw materials required will vary slightly due to differences in moisture content and production processes.

2.Moisture content:

Making charcoal requires raw materials with very low moisture content. Ordinary wood or newly cut wood has a relatively high moisture content. The moisture content of the former is basically above 35%, and the moisture content of the latter is as high as 50%-60%. Therefore, you need to pay more attention when choosing raw materials.

The moisture content of wood

The moisture content of wood

Due to different moisture content and different production process operations, the amount of raw materials required will vary. Raw materials with higher moisture content will require more input weight since a significant portion of the initial weight will be lost in the form of water vapor during drying. If the moisture content of the raw materials is around 40%-50%, then approximately 5 tons of raw materials are needed to produce one ton of charcoal. If the moisture content is below 40%, the demand for raw materials will decrease.

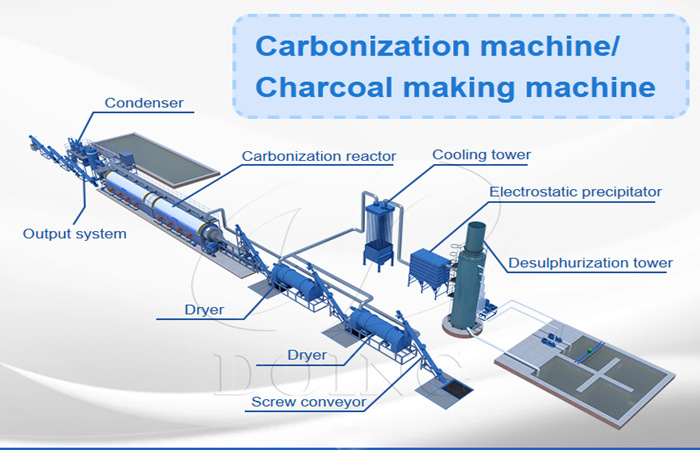

3.Production process efficiency:

A more efficient technology of charcoal making machine minimizes heat loss and incomplete combustion, thereby increasing the proportion of charcoal produced. DOING charcoal making machine is an environmental friendly machine that uses pyrolysis technology to convert biomass waste into charcoal under anaerobic and high-temperature conditions.

Charcoal making machine

Charcoal making machine

In addition, our charcoal making machine not only has high production efficiency and good stability, but can also continuously produce high-quality charcoal, meeting market demand and bringing good benefits. The combustible gas generated during carbonization process can be recycled as fuel in the furnace, greatly reduce energy consumption and save cost.

4.Charcoal quality and desired properties:

Producing high-quality charcoal with specific properties (e.g., low ash content, high calorific value) may require a more selective raw material or a longer pyrolysis time, which could affect the conversion ratio.

Henan DOING company has more than thirteen years of professional knowledge, focusing on waste recycling machinery. DOING charcoal making machine can help you do it more efficiently and with less waste, allowing you to maximize your profits. If you want to know more details, please contact us.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.