WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How much do you know about lithium battery recycling machine?

April 9, 2024

April 9, 2024- FAQ

- Leave a message

- Chat online

Benefiting from the strong demand in markets such as new energy vehicles, mobile phones, laptops, and digital products, the lithium battery recycling industry will continue to maintain a growth trend. Lithium battery recycling machine is crucial to the lithium battery recycling industry. How much do you know about lithium battery recycling machine? In the following article, I will give a brief introduction to lithium battery recycling machine.

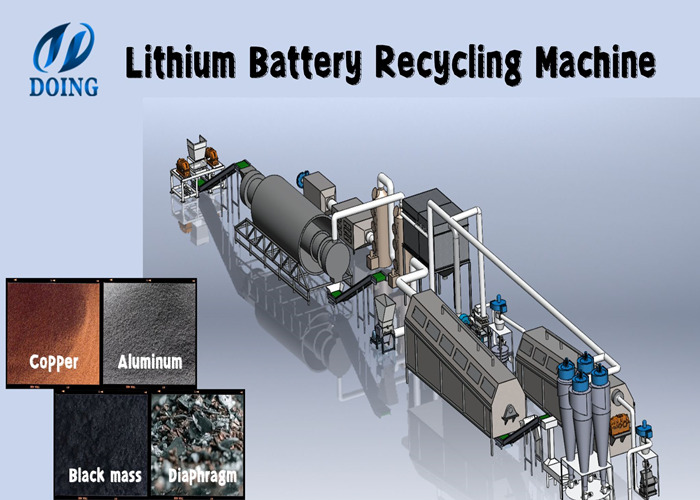

1.What is lithium battery recycling machine?

The lithium battery recycling machine uses mechanical crushing, carbonization and physical screening technology to recover valuable materials such as copper or aluminum, black matter, etc. from lithium batteries. With the help of lithium battery recycling machine, we can separate pure metal and graphite, which not only brings huge economic benefits, saves the cost of raw materials for manufacturing new lithium batteries, but also reduces the negative impact on environmental pollution.

Lithium battery recycling machine

Lithium battery recycling machine

2.What is the process of lithium battery recycling machine?

1. Discharge tank: Discharging used lithium batteries to a non-electric state by self-discharging or immersing them in salt water.

2. Conveyor belt: Transporting the uncharged lithium batteries to the shredder.

3. Double shaft shredder: Lithium batteries are shredded into small pieces for further processing by subsequent equipment.

4. Carbonization equipment: Carbonization is used to remove diaphragms, electrolytes, organic materials, and other contaminants.

5. Crusher: Crushing lithium batteries into 8-20mm pieces for further process.

6. Magnetic separator: Removing the iron from the lithium battery.

7. Vibrating sieving: Through the multi-layer sieve, several specifications of oversize and undersize materials are produced, and are discharged from their respective outlets.

8. Grinder: Grinding the metal into 15-20 mesh powder.

9. Air separator: The ground powder is separated into copper, aluminum, black mass, etc. The separation rate of copper and aluminum in this process is about 98%.

10. The tail gas treatment system: the pyrolysis tail gas is treated to meet environmental protection standards before being discharged.

3.What is the product of lithium battery recycling machine?

The products of lithium battery recycling machine

The products of lithium battery recycling machine

After processing by lithium battery recycling machine, we can get pure copper, aluminum, diaphragm and black mass. The copper and aluminum separated can be sold directly to the metal trading market for profit. Black powder mainly includes graphite powder and lithium cobalt oxide, both of which are widely used. Taking graphite powder as an example, graphite powder can be used in many aspects such as environmental protection, energy conservation and industrial product manufacturing, and has high utilization value.

4.What is the benefits of lithium battery recycling machine?

1.The equipment design is compact and reasonable. The entire production line is composed of several single-machine links, which is convenient for maintenance.

2. Lithium battery recycling machine operates under negative pressure, without dust leakage, and the separation efficiency can reach more than 99%.

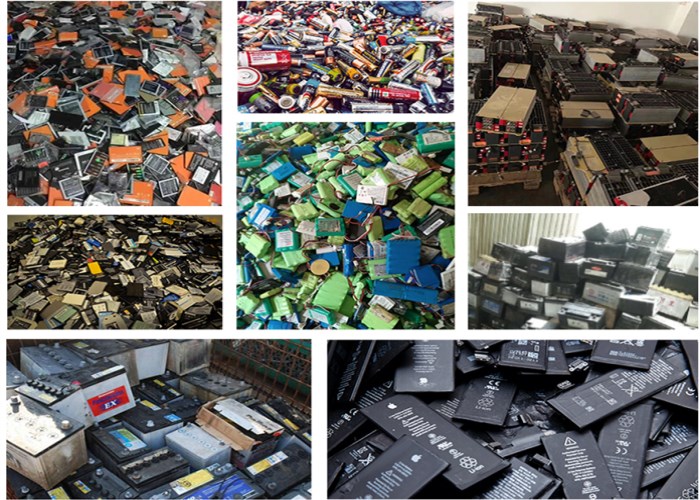

3. Wide scope of application: The lithium battery recycling machine can be used to recycle mobile phone batteries, car batteries, rechargeable batteries, electric vehicle lithium batteries, soft pack batteries, hard-shell batteries, cylindrical batteries, etc.

Waste lithium batteries

Waste lithium batteries

4. The final product can be used for secondary use and has a very high economic value.

5. With PLC control system, easy to operate; saving power, saving manpower and high efficiency.

6. Can be customized according to the actual needs of customers.

5.Is the lithium battery recycling business profitable?

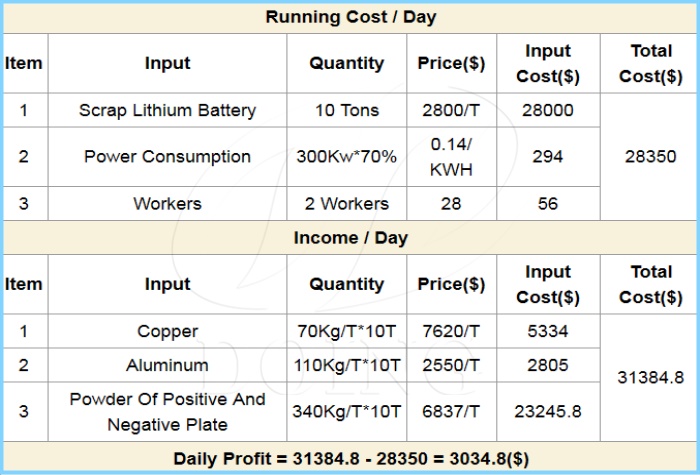

Due to factors such as the different purity of the sorted products, fluctuations in market prices of raw materials and products, and other factors, the final profits are uncertain. The data in the below table is for reference only.

Profit analysis

Profit analysis

Henan DOING has been committed to providing customers with high-quality and high-efficiency lithium battery recycling machine. If you are interested in lithium battery recycling business, and want to know more details, please contact us.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.