WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How much does it cost to set up a solar panel recycling plant?

May 21, 2024

May 21, 2024- FAQ

- Leave a message

- Chat online

As solar panels reach the end of their useful life, the need for proper disposal and recycling of solar panels is growing. Setting up a solar panel recycling plants is a critical step towards sustainable energy practices.

Setting up a solar panel recycling plant requires adequate market research and careful planning. The cost of setting up such a solar panel recycling plant will vary greatly due to a variety of factors, such as location, size, technology and machine, and regulatory compliance. In this article, we will explore the factors that influence the cost of setting up a solar panel plant.

1.Technology and machine:

Adequate market research will help you understand the latest recycling technologies, machine and regulations. This step will help determine the most efficient and environmentally friendly process for your solar panel recycling plant. The main purpose of recycling solar panels is to extract and reuse valuable materials such as silicon, glass, metals (such as aluminum and copper), while reducing environmental pollution and resource waste. Here are a few common methods to recycle solar panels and their pros and cons.

1.1 Heat treatment method

Heat treatment method can effectively separate different materials at high temperatures, especially the separation of glass and metal. However, it requires high-temperature heating and consumes a lot of energy. Therefore, solar panel recycling machine made using this technology is not only expensive but also requires a complete exhaust gas treatment system.

1.2 Chemical treatment method

The chemical treatment method has a high recovery rate and can recover precious metals and silicon more thoroughly. The recycled materials are of higher quality and are suitable for remanufacturing. But, the use of chemical reagents may produce wastewater, and meeting discharge standards requires a large investment of money and time.

1.3 Mechanical recycling method

Mechanical recycling method can process a large number of waste solar panels in batches and is suitable for industrial production. The mechanical recycling method involves the crushing and separation technology, which not only has a high sorting effect, but also produces more products such as silicon, glass, copper, aluminum, and plastic. Compared with other methods, the environmental pollution produced is smaller.

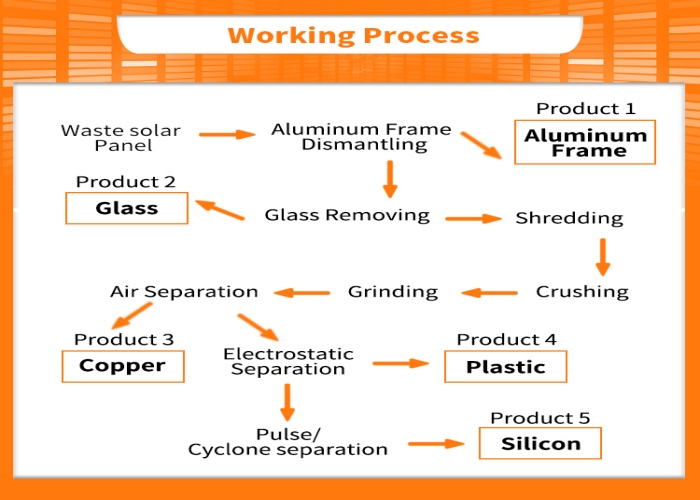

The working process of mechanical recycling method

The working process of mechanical recycling method

Investing in proper solar panel recycling machine is vital for solar panel recycling plant. Choosing the most appropriate recycling method requires comprehensive consideration of economics, environmental impact, technological maturity, and the final use of the material.

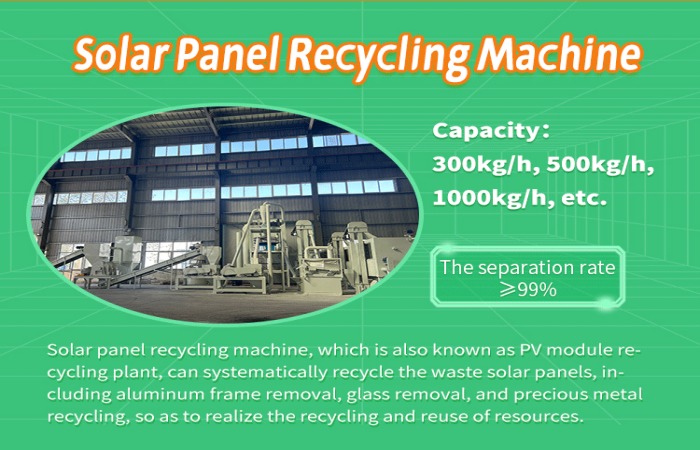

DOING solar panel recycling machine

DOING solar panel recycling machine

DOING solar panel recycling machine including aluminum frame removing machine, glass removing machine, crushing and sorting machine can efficiently recycle solar panels to obtain silicon, copper, plastic and glass, thereby realizing resource recycling and reuse. Besides, the processing capacity of our solar panel recycling machine ranges from 400-1000kg/h. The price of the solar panel recycling machine is between 70,000 and 230,000, and the price range will be larger due to factors such as processing volume and equipment configuration. DOING solar panel recycling machine is not only more cost-effective, but also has guaranteed quality, technical support and service. Therefore, purchasing a solar panel recycling machine from our factory is a wise choice for pursuing efficient operations.

2.Location and Space:

Choosing an appropriate location for your solar panel recycling plant is crucial. The cost of purchasing or leasing land and building a factory will vary based on location and size. It is worth noting that due to different processing capabilities, the footprint of solar panel recycling machine also varies. Therefore, when deciding to set up a solar panel recycling plant, you need to ensure that the space you choose is large enough to accommodate the solar panel recycling machine, raw material and product storage areas, etc.

Factory

Factory

3.Working Capital:

Operational costs like labor, maintenance, raw material, and logistics need to be considered alongside the initial setup costs.

4. Regulatory Compliance:

Adhering to local, national, and international regulations is essential for the success of your recycling plant. Understand the legal requirements for handling hazardous materials, waste disposal, and emissions control. Complying with these regulations may involve additional costs, such as obtaining permits, licenses, and certifications.

From factory planning, solution formulation, solar panel recycling machine supply and installation, Henan Doing, as a professional manufacturer of waste recycling machinery, can provide one-stop services at relatively preferential prices. If you have any concerns or need more details, please feel free to contact us.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.