WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How to choose the right solar panel recycling equipment?

July 23, 2024

July 23, 2024- FAQ

- Leave a message

- Chat online

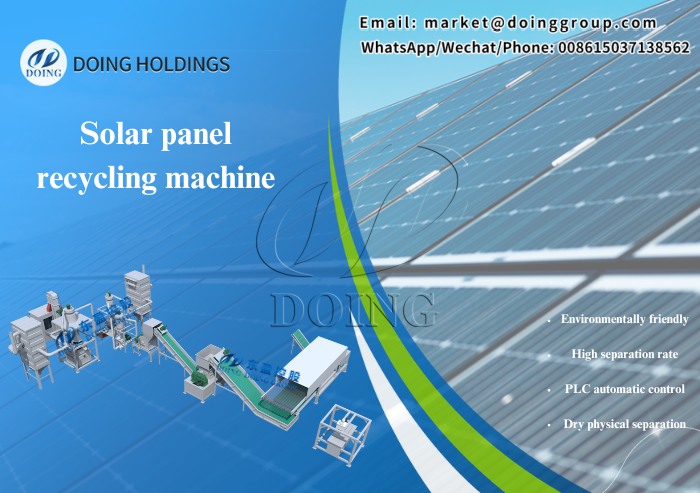

Solar panel recycling equipment is a machine that processes waste solar photovoltaic panels to extract high-value metal resources such as copper, aluminum, silicon, etc. When investing in a waste solar panel recycling business, the most important project preparation is to choose the right solar panel recycling equipment. Generally, you should consider the following key factors:

Solar panel recycling equipment

Solar panel recycling equipment

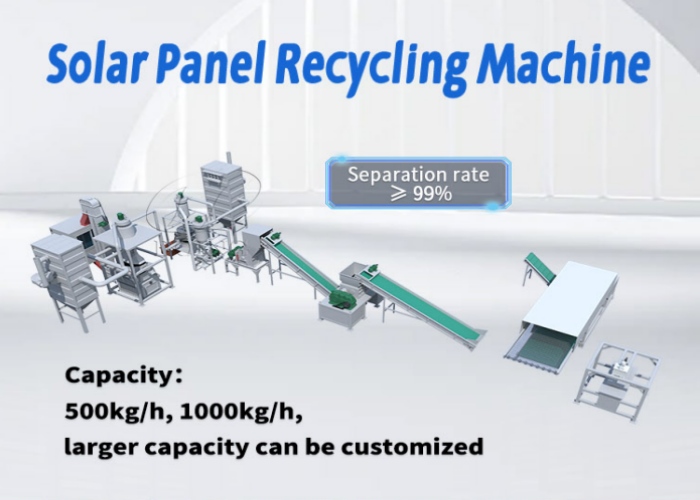

1. Processing capacity

Different equipment has different processing capacities, ranging from tens of tons to hundreds of tons per day. For start-ups or small recycling companies, they may prefer equipment with a daily processing capacity of tens of tons, which can not only meet the initial business needs, but also avoid excessive capital investment in the initial stage. As the business expands and market demand increases, companies can gradually upgrade to equipment with higher processing capacity to adapt to higher processing volumes.

Solar panel recycling equipment

Solar panel recycling equipment

Medium-sized companies usually need equipment that can process about 100 tons per day to maintain efficient operation and continuous growth of the business. Large recycling companies or industrial-grade recycling centers need equipment that can process hundreds of tons per day. Choose a solar panel recycling equipment that can meet your needs based on the scale of your business and expected processing volume.

2. Product recovery rate

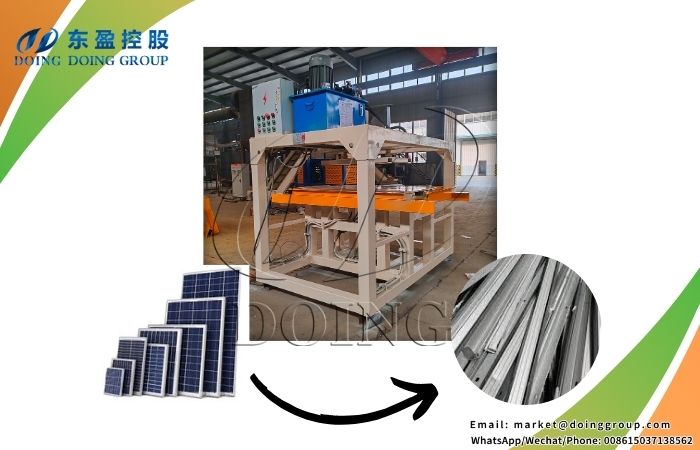

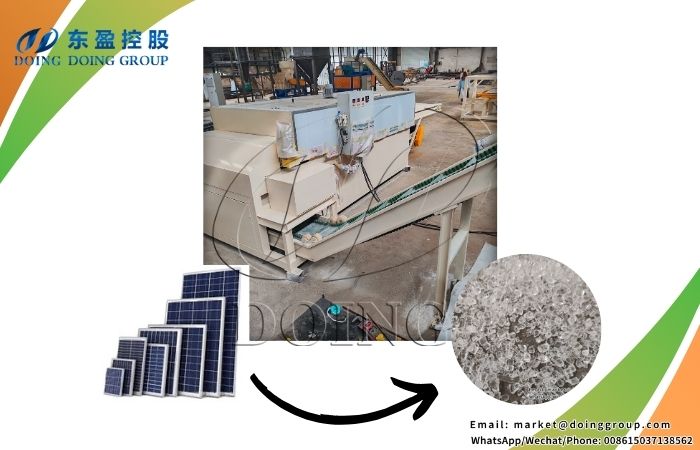

The recycled products of solar panels include copper, aluminum frames, silicon, plastic, glass, etc. Among them, aluminum and copper are mainly used for frames and conductive lines in solar panels, and are metal materials with high recovery value. By selecting equipment with efficient metal separation technology, the recovery rate of aluminum and copper can be maximized.

3. Equipment quality and durability

Choosing equipment with good quality and strong durability can reduce long-term operating costs and increase the service life of the equipment. There are many suppliers of solar panel recycling equipment on the market, and companies should carefully evaluate the performance records of various brands and models when choosing.

Solar panel recycling equipment

Solar panel recycling equipment

By referring to industry analysis reports, customer reviews, and after-sales service commitments of equipment, the quality and durability of equipment can be judged more accurately. In addition, on-site inspections of the operating conditions of the equipment and technical exchanges with suppliers are also important steps to ensure the selection of high-performance equipment.

4. Technology maturity

Give priority to equipment with mature technology and market verification. These equipment are usually more reliable, have a low failure rate, and have low maintenance costs. Equipment with mature technology and market verification is relatively simple in daily maintenance and maintenance due to its more reasonable design and more sophisticated manufacturing process, and has lower maintenance costs. This will not only reduce equipment downtime and improve production efficiency, but also save a lot of maintenance costs in long-term operations, creating higher economic benefits for the recycling business.

5. Environmental standards

During the recycling process, improper treatment methods may cause secondary pollution, such as heavy metal leakage and harmful gas emissions, which not only violate environmental regulations, but also may threaten the surrounding environment and residents' health. Choosing equipment that can effectively control secondary pollution, such as equipment equipped with high-efficiency filtration systems and harmless treatment technology, can significantly reduce environmental pollution.

6. After-sales service and technical support

Prefer manufacturers that provide comprehensive after-sales service and technical support to obtain timely help and solutions during the operation of the equipment.

Solar panel recycling equipment

Solar panel recycling equipment

DOING solar panel recycling equipment can be customized according to different production capacity requirements to meet the processing capacity of 500kg to 2000kg per hour or even higher. The equipment is equipped with advanced frame removal machines and glass removal machines, as well as high-quality and long-life shredders, magnetic separators, grinders, electrostatic separators, etc., ensuring a product recovery rate of up to 99%.

After-sales service

After-sales service

In terms of environmental protection, our equipment is equipped with a pulse dust removal system to strictly control the emission of harmful gases and dust. In order to protect the interests of customers, we also provide comprehensive after-sales service and technical support to ensure the stable operation and efficient output of the equipment. If you are interested in DOING solar panel recycling equipment, you are welcome to call us for consultation or visit our factory.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.