WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How much material can a lithium battery recycling equipment recover from lithium batteries?

July 25, 2024

July 25, 2024- FAQ

- Leave a message

- Chat online

Lithium-ion batteries, commonly found in smartphones, laptops, electric vehicles (EVs), and grid storage systems, contain a multitude of valuable and reusable materials. Recycling these batteries not only reduces the dependency on raw material extraction but also mitigates environmental hazards associated with improper disposal. The amount of materials that can be recycled from waste lithium battery through lithium battery recycling equipment largely depends on the type of lithium batteries, the recycling technology used, and the recycling efficiency.

Types of Lithium Batteries and Their Composition

Lithium-ion batteries are composed of four main components: cathode, anode, electrolyte, and separator. The cathode is responsible for storing lithium ions during discharge and typically contains metals such as lithium, nickel, cobalt, manganese, or aluminum, all of which are critical to battery manufacturing. Advanced recycling processes can recover a large portion of these metals, with recycling efficiencies varying depending on the specific chemistry. The anode, usually made of graphite, releases or absorbs lithium ions during charging and discharging. Graphite is highly recyclable and can be recycled to produce new batteries or other industrial applications. The electrolyte facilitates ion movement between the cathode and anode, while the separator prevents physical contact between the two to prevent short circuits. The battery's casing, typically made of plastic or metal, can also be recycled, aiding overall material recovery.

The types of lithium battery

The types of lithium battery

Recycling Efficiency and Technologies

The efficiency of lithium-ion battery recycling varies widely, with reported rates ranging from around 50% to over 90% of materials by weight, depending on the recycling technology and the specific battery type being processed.

Mechanical Processing: This involves the dismantling and separation of waste lithium batteries, which forms the basis for further processing of the individual components.

Pyrometallurgical Processes: These involve high-temperature smelting to recover metals like copper, aluminum, and some of the cathode metals. While effective for certain elements, this method can result in lower recoveries of lithium and is less environmentally friendly due to emissions.

Hydrometallurgical Processes: A more sophisticated approach, hydrometallurgy uses chemicals to dissolve metals from battery materials. This method allows for better selectivity and higher recoveries of lithium and other metals, but requires careful handling of hazardous chemicals and waste.

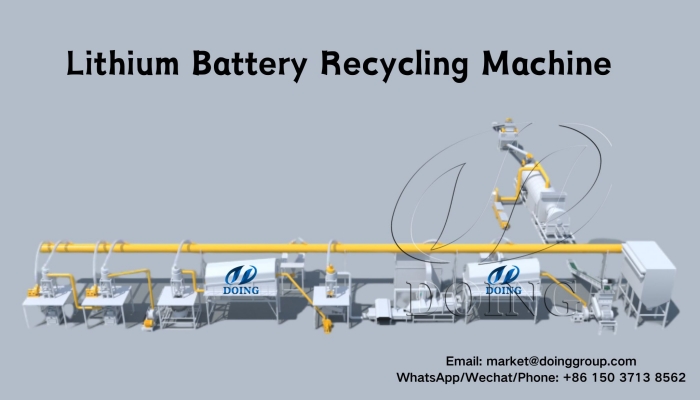

Lithium battery recycling equipment

Lithium battery recycling equipment

Advanced lithium-ion battery recycling technology and equipment play a key role in solving lithium battery waste treatment and resource recovery. As a manufacturer with over 14 years of experience in manufacturing waste recycling machinery, Henan DOING have a professional team of engineers who are dedicated to providing the best quality solutions. DOING lithium battery recycling equipment integrates crushing, carbonization, screening, conveying and other technologies to recover copper, aluminum and black mass from waste lithium batteries. Through the combination of different devices, a highly automated and efficient recycling production line is formed to complete the processing operations required for the recycling of waste lithium batteries, and the operation is stable and reliable.

Lithium battery recycling equipment

Lithium battery recycling equipment

At the same time, DOING lithium battery recycling equipment is equipped with an intelligent negative pressure system, a remote operating system, a safety monitoring and protection device, and an advanced environmental protection system, making the entire recycling process simpler, highly controllable, and environmentally friendly. In addition, our lithium battery recycling equipment can process different types of lithium-ion batteries, greatly improving the flexibility and efficiency of recycling.

DOING is committed to the research and development of lithium-ion battery recycling technology and the manufacture of efficient lithium battery recycling equipment. If you have any questions or needs, please feel free to contact us for consultation.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.