WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Will solar panel recycling machine generate pollution during operation?

December 31, 2024

December 31, 2024- FAQ

- Leave a message

- Chat online

The solar panel recycling machine is specially used to process scrapped solar photovoltaic panels into aluminum frames, glass, metal, silicon and plastic. Solar panel recycling process mainly includes steps such as dismantling, crushing and separation. The solar panel recycling machine is easy to install and has high working efficiency. However, some inevitable hidden dangers potential contaminants will occur during the operation. Let’s take a look at the specific pollution factors and countermeasures.

Solar panel recycling machine

Solar panel recycling machine

Pollution generated during the operation of solar panel recycling machine:

Solar panel recycling machine adopts a fixed production line and operates on a large scale. It is worth noting that the entire solar panel recycling production line designed by Henan DOING mainly uses physical methods to work. The advantage of physical recycling method is that it avoids the use of chemicals, thus significantly reducing the possibility of chemical contamination. However, physical recycling process is not without potential contamination risks, and the most prominent potential contaminant is dust.

Dust pollution

Dust pollution

The operation process of the solar panel recycling machine mainly includes: aluminum frame removal → glass removal → shredding → crushing → grinding → screening → separation. When operations such as crushing and grinding waste photovoltaic panels are performed, a certain amount of dust will inevitably be generated. However, there is no need to worry too much, because solar panel recycling machine production lines are equipped with high-efficiency dust collectors.

How does the solar panel recycling machine ensure environmental protection?

Although there is dust pollution in the physical recycling process of solar panel recycling machine, by equipping it with a high-efficiency environmental protection facilities, dust particles in the air can be effectively captured and prevent them from being directly discharged to the environment and causing air pollution.

Pulse dust collectors

Pulse dust collectors

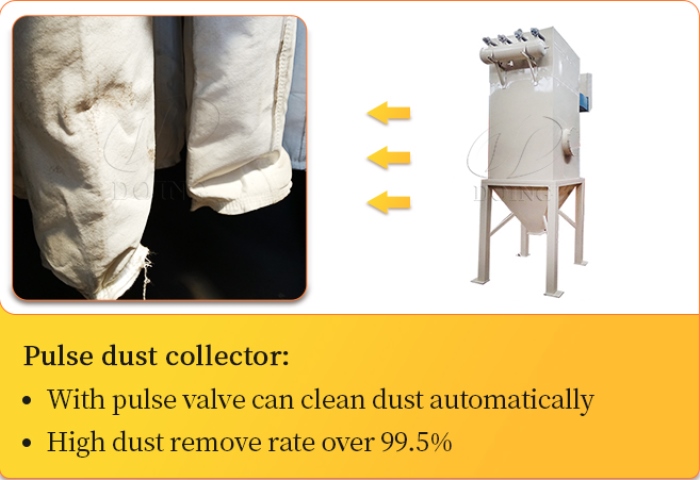

After research, Henan DOING's equipment manufacturing engineers connected pulse dust collectors to the entire production line of solar panel recycling machine to centrally collect and clean dust pollution. The pulse dust collector can firmly lock the dust, and the exhaust gas is discharged after layers of purification, without causing secondary pollution. Pulse dust collector has the advantages of high efficiency, stability and easy operation. Its purification efficiency is as high as 99%, its performance is stable, the filter bag has a long life, and the maintenance workload is small.

Solar panel recycling machine

Solar panel recycling machine

As the number of scrapped photovoltaic panels increases, the business of recycling scrap solar panels will become more and more popular. Recyclable components of solar panels include high-quality glass, aluminum frames, EVA, silicon, copper and silver, among others. All these components can be successfully recycled by our solar panel recycling machine without causing dust pollution and complying with environmental protection requirements. If you are interested in Henan DOING solar panel recycling machine and seek more details, please feel free to contact us.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.