WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How is barbecue charcoal produced?

December 26, 2024

December 26, 2024- FAQ

- Leave a message

- Chat online

As barbecue becomes more and more popular around the world, the market demand for barbecue charcoal has also increased, and the business of producing barbecue charcoal has gradually attracted the attention of investors. This article introduces the production process of barbecue charcoal in detail from the aspects of types of barbecue charcoal, raw materials for making barbecue charcoal, and production process.

Barbecue charcoal

Barbecue charcoal

Types of barbecue charcoal:

Most barbecue charcoal can generally be divided into natural charcoal and machine-made charcoal. Here are the differences between these two types of barbecue charcoal:

Natural charcoal: Natural charcoal is made by direct combustion and carbonization of raw materials, most of which are irregular in shape. Natural charcoal burns faster and is suitable for use as ignition charcoal.

Mechanical charcoal: Mechanical charcoal is produced and processed by barbecue charcoal making machine. Mechanical charcoal is smokeless and dustless during the combustion process, has a regular shape, and is easy to use. The burning time of machine-made charcoal is 3 times that of natural charcoal, and it is environmentally friendly and smokeless, and it is not easy to start an open flame.

Barbecue charcoal

Barbecue charcoal

Raw materials for barbecue charcoal:

The main raw materials of barbecue charcoal include wood, bamboo, coal, and coconut shells.

1. Wood: The most common raw material for barbecue charcoal is wood, especially fruit charcoal, which is usually made of apple wood, pear wood, jujube wood, etc. These fruit charcoals will emit a unique fragrance when burning, which is particularly suitable for barbecue food that needs a smoked flavor.

2. Bamboo: Bamboo charcoal is made of bamboo, has a longer burning time, and the taste of the grilled food is more delicate. Bamboo charcoal is environmentally friendly and non-toxic, with fewer sparks when burning, and is relatively safer.

3. Coal: Coal is relatively cheap, and it will produce thick smoke and odor during the combustion process.

4. Coconut shell: Coconut shell charcoal is made of coconut shells. The meat grilled with coconut shell charcoal has a fragrant taste, and the price is relatively affordable, and it is also more popular in the market.

Raw materials for barbecue charcoal

Raw materials for barbecue charcoal

How to produce barbecue charcoal?

Through the above introduction, we know that barbecue charcoal can be made with wood, bamboo, fruit shells and other raw materials. Next, let's introduce how to produce barbecue charcoal with these raw materials.

1. Choose the right equipment

Barbecue charcoal making machine is the key equipment for making barbecue charcoal, which is mainly divided into continuous and intermittent types. If you are a family workshop, the intermittent carbonization furnace is more suitable for you. Because the intermittent carbonization furnace is relatively simple to operate and the equipment cost is relatively low.

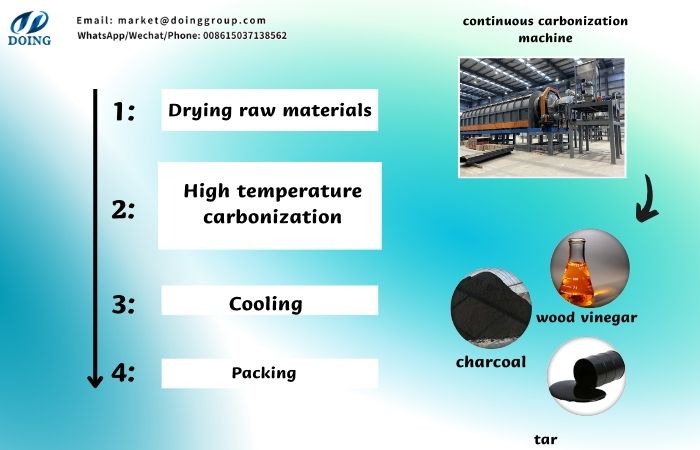

For large-scale and commercial producers, the continuous carbonization furnace is more suitable. The continuous carbonization furnace can produce 24 hours a day without interruption and has high production efficiency. Since certain technical support is required to ensure stable operation, the equipment cost is also relatively high. But once an efficient production process is established, a large amount of high-quality barbecue charcoal can be produced quickly, thereby obtaining a high profit return.

Barbecue charcoal making machine

Barbecue charcoal making machine

2. Steps for making BBQ charcoal

Step 1: First, crush and dry the collected biomass waste to facilitate subsequent carbonization and improve the quality of barbecue charcoal;

Step 2: Send the pretreated fruit shell raw materials into the high-temperature carbonization furnace to convert them into charcoal. The gas generated during the carbonization process will be collected and recycled as combustible gas through the condensation system to achieve energy circulation;

Step 3: The produced barbecue charcoal can be collected after cooling to a safe temperature. It can be processed into regular size and shape later with a charcoal briquetting machine.

Steps for making BBQ charcoal

Steps for making BBQ charcoal

The above is a complete introduction to the production process of barbecue charcoal. As consumers pay more attention to environmental protection and green energy, the demand for charcoal market continues to grow. Especially in developed countries and some emerging markets, outdoor barbecue and camping activities are becoming more and more popular, which will further promote the development of charcoal market and bring considerable profits. If you are also interested in the barbecue charcoal production project, please consult Henan DOING. Our barbecue charcoal making machine can produce high-quality barbecue charcoal, and the equipment has been sold to Vietnam, India and other regions. Welcome to leave a message about your questions, and we will have professionals to answer them for you.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.