WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

What are the separation and recycling techniques of e-waste?

August 16, 2023

August 16, 2023- FAQ

- Leave a message

- Chat online

Nowadays, there are four kinds of e-waste separation and recycling techniques used in e-waste separation and recycling business: Manual separation and recycling techniques, chemical separation and recycling techniques, mechanical separation and recycling techniques and pyrolysis separation and recycling techniques.

If you want to start e-waste separation and recycling business, you can choose suitable e-waste separation and recycling techniques based on your business scale and actual requirement, and find good manufacturer to purchase e-waste separation and recycling machine.

E-waste

E-waste

If you have a small business scale that just removes electronic components from computer boards or other boards, manual separation and recycling techniques are better. However, this method is time-consuming and labor-intensive, and the efficiency is low. Profits are relatively less and limited by the number of bare boards and electronic components to disassemble. So if you want to get more profit, it is recommend to add a PCB dismantling machine for your e-waste separation and recycling business.

Henan DOING has two models PCB dismantling machine: 300kg/h and 500kg/h. You can choose based on your daily processing capacity of waste circuit boards. In addition, DOING PCB boards dismantling machine has two ways to heat: electric heating and gas heating. Also you can choose according to actual condition for your business.

PCB dismantling machine

PCB dismantling machine

Choosing effective e-waste separation and recycling techniques are necessary when you have a large amount of e-waste. Which one is better, chemical separation and recycling techniques or mechanical separation and recycling techniques, depends on your actual requirements.

Chemical separation and recycling techniques involve the use of chemical reactions and specialized equipment to separate and recycle valuable metals from e-waste. Some common chemical separation and recycling techniques include: extraction, solvent extraction, electrolysis and so on.

Chemical separation and recycling techniques

Chemical separation and recycling techniques

If you want to get profit from different metals, the chemical separation and recycling techniques are suit for you. But, the wastewater during process is still a difficult question that need to resolve. And the cost is much higher because of the need for professional operators and the discharge of wastewater after treatment.

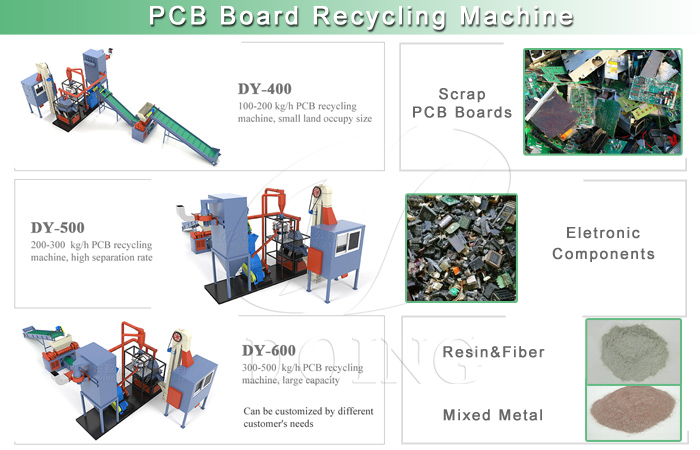

Mechanical separation and recycling techniques are adapts dry type physical crushing and separating principles to recycle mixed valuable metals and resin &fiber from e-waste. The main process contains shredding, crushing, screening, and separating. Each part has special machine that fully uses the physical properties of metal and nonmetal.

E-waste separation and recycling system

E-waste separation and recycling system

The mechanical e-waste separation and recycling machine is an environmental friendly machine used to dispose of e-waste without causing any pollution. Besides, e-waste recycling machine is easy to operation and save labor. The only problem is that the price is relatively high than chemical machines.

The difference between these two techniques are the products. If you want to get different metal, you can choose chemical e-waste separation and recycling machine or the combination of mechanical e-waste recycling machine and metal purification liquid.

Henan Doing Company is specialized in waste recycling machine more than twelve years, and we have own high qualified engineer team. If you are interested in e-waste separation and recycling business and want to purchase an environmental friendly machine. Our company can provide you a nice scheme. Besides, our e-waste separating and recycling machine has different processing capacities for you to choose from, ranging from 200-300kg/h to 1t/h. For more capacity, we provide customized service.

E-waste separation and recycling machine

E-waste separation and recycling machine

Pyrolysis separation and recycling techniques process e-waste to get solid products, gas products, and oil. The solid product contains easily separated metal components, glass fibers and other. The main components of gas products are CO2 and CO.

Pyrolysis technology has great potential for processing waste circuit boards because the operation is simple, and the reaction process is fast. During the pyrolysis process, the resource recovery rate is high, especially the recovery rate of tin, aluminum, and magnesium is greatly improved. However, the cost is very high due to the large land occupation of factory and the price of pyrolysis machines, which can be expensive to set up and maintain. And gas produced is harmful to the environment.

Pyrolysis separation and recycling system

Pyrolysis separation and recycling system

As people's awareness of environmental protection increases day by day, some businesses that pollute the environment may be replaced by more environmentally friendly methods. Taking these into consideration, the mechanical e-waste separating and recycling machine is more suitable for someone that are new to recycling business. At the same time, the e-waste separating and recycling machine can meet the requirements of expanding business scale in the future.

If you are interested and want to know more information about the e-waste separating and recycling machine. You can contact us, and we will give you our best support.

Contact Us

- Email:

- Tel/WhatsApp:

News

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.