WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

What is the core equipment in the lithium battery recycling process?

February 29, 2024

February 29, 2024- FAQ

- Leave a message

- Chat online

With the development and widespread application of lithium-ion batteries in electric vehicles, the problem of battery waste disposal and recycling has become increasingly prominent. Improper handling can have a negative impact on the environment and resources. Therefore, the recycling and reuse of scrap lithium batteries is very important. Here will introduce the core equipment in the lithium battery recycling process.

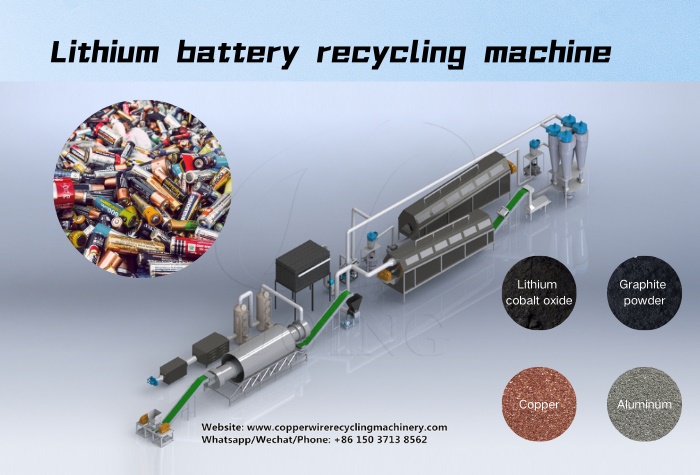

Lithium battery recycling machine

Lithium battery recycling machine

The process flow of lithium battery recycling machine is divided into three core parts: crushing, sorting and carbonization furnace. After the battery is discharged, copper, aluminum, graphite powder and cobalt acid lithium are separated through multiple crushing and sorting. The dust generated during the entire process will be purified and discharged after meeting the standards.

The core equipment in the lithium battery recycling process:

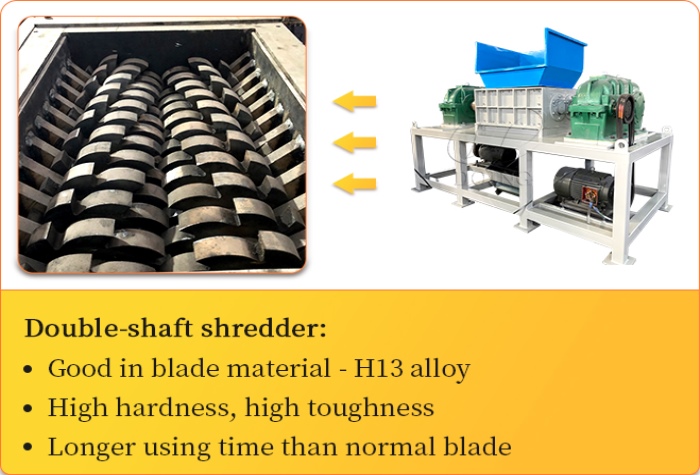

1. Double-shaft shredder:

The double-shaft shredder structure is specially designed to optimize the grab, tear and cut of the material. Belt conveyor can transport scrap lithium battery to double shaft shredder to preprocess. After processing, used lithium batteries can be shredded into pieces of about 2-5cm. The blade claw, diameter and thickness could be customized according to input material and discharge size.

Double-shaft shredder

Double-shaft shredder

2. Carbonization furnace

The carbonization furnace uses electric heating, and the temperature in the furnace is designed to be 500-600°C. It takes about 15-20 minutes for the broken materials to enter the furnace and be discharged. As the furnace rotates, the completely carbonized materials are discharged from the discharge port.

Carbonization furnace

Carbonization furnace

3. Dust and Gas Cleaning System

Gas cleaning system is mainly composed of spraying tower system, activated carbon system and UV photooxygen catalytic system. Dust collector system mainly uses dual dust removal systems of cyclone dust removal and pulse dust removal to work together. After the dust-containing gas enters the dust collector, the filtered gas meets the emission standards.

4. Crushing :

4.1 Crusher

The hammer crusher is a commonly used crushing equipment suitable for crushing lithium batteries. It has a high-speed rotating hammer head that can break batteries into small pieces for subsequent processing, and can be customized and produced according to customer needs.

4.2 Grinder

Grinder will grind raw material (mostly are copper and aluminum) as a granular shape.

5. Separation:

5.1 Rotary Screen

Through rolling and rotating screening, qualified materials (battery powder) are discharged through the sieve holes. By adjusting the size of the surface of rotary screen, about 95% of the black powder can be recovered.

5.2 Magnetic Separator

Magnetic separator is mainly used to remove ferromagnetic materials from non-magnetic materials in small granules or powder.

5.3 Vibrating Screen

Linear vibrating screen is a commonly used sorting equipment. Under the action of vibration, the vibrating screen classifies and separates particles of different sizes according to particle size and weight.

Vibrating Screen

Vibrating Screen

Eddy-vibrating screen is a high-precision screening machine with low noise, high efficiency and whole sealing structure, applicable to sieve granular, powdery materials. The recycling rate of black powder is about 99% in this process.

5.4 Air Separator

With the effect of air flow and vibration friction, the heave gravity of materials (copper) will settle to the bottom layer, then move upward through the vibration friction on the screen, the light gravity of materials (aluminum) are suspended on the surface of materials, moving downward through air flow, thus to get separated. The separation rate of copper and aluminum in this process is about 98%.

Air Separator

Air Separator

Doing's lithium battery recycling machine adopts high-efficiency crushing and separation technology, as well as carbonization technology to achieve more refined and higher-purity recycling of metals and positive and negative polarities, further improving resource reuse and environmental friendliness.

Our lithium battery recycling machine can assist you in achieving this goal by enhancing efficiency and minimizing waste, thereby maximizing your profits. If you are interested and would like more information, please do not hesitate to get in touch with us.

Contact Us

- Email:

- Tel/WhatsApp:

FAQ

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.