WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Can lithium batteries for electric cars be recycled? How to recycle?

December 9, 2023

December 9, 2023- FAQ

- Leave a message

- Chat online

Lithium batteries for electric cars are completely recyclable. Lithium batteries contain a variety of valuable metal resources, such as lithium, cobalt, nickel, manganese, copper, etc. These materials can be extracted and reused through scientific and reasonable recycling processes. The recycling of lithium batteries for electric vehicles is not only an effective way to solve environmental problems and resource scarcity, but also a key link in promoting the healthy and sustainable development of the new energy vehicle industry.

However, the lithium batteries are flammable and explosive, they may pose hidden dangers during recycling. Therefore, recycling lithium batteries for electrical cars requires selecting appropriate recycling technology and corresponding equipment - lithium battery recycling machines.

1.The main technology of lithium battery recycling:

Physical separation technology:

Physical recycling technology refers to the process of crushing, screening, magnetic separation, fine crushing and classification of the internal components of used power batteries to obtain valuable products. Although the processing efficiency of physical dismantling and recycling is lower, the process is very environmentally friendly because no additional chemicals are consumed.

Pyrometallurgical (high temperature metallurgy) technology

The pyrometallurgical technology means that the carbon and organic matter in the electrode fragments will be burned away at high temperature, and finally fine powder materials containing metals and metal oxides will be obtained through screening. The pyrometallurgical process is relatively simple and has high compatibility, but the combustion of battery electrolytes and other components in the electrodes can easily cause air pollution, and the pressure of incineration exhaust gas treatment is high.

Pyrometallurgical

Pyrometallurgical

Chemical dissolution technology:

Chemical dissolution technology mainly refers to the use of media such as acid and alkali solutions to extract metal ions from electrode materials, and then converts the metal ions in the solution into metal compounds through ion exchange, precipitation, and extraction to extract them. Although the chemical process is complex, the cost is relatively high and the environmental protection requirements are high.

2.Lithium battery recycling machine:

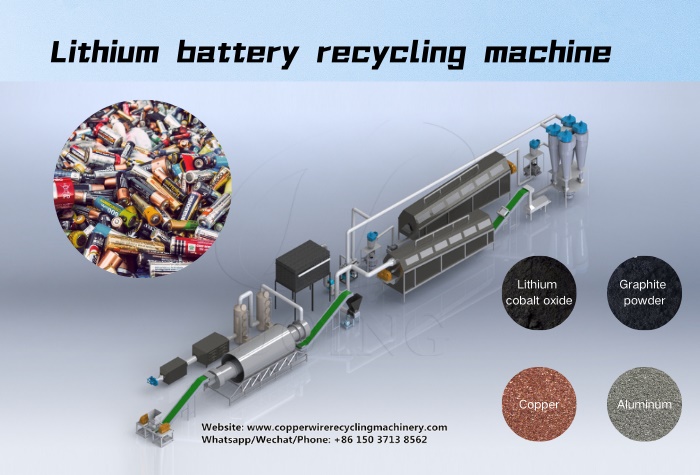

In order to meet market demand and improve production efficiency, our company designs and produces lithium battery recycling machine, which can be used for recycling of soft pack batteries, mobile phone batteries, case batteries, cylindrical lithium batteries, etc.

Lithium battery recycling machine

Lithium battery recycling machine

Doing’s lithium battery recycling machine adopts mechanical crushing, physical separation and carbonization technology to achieve efficient separation and recovery of used lithium batteries. The process of lithium battery recycling machine is as follows:

1.Discharged

Put the used lithium battery into 8%-15% NaCl Solution for 48 hour, so that the positive and negative terminals of the battery are short-circuited, let battery discharge completely.

2.Shredding and Crushing

The discharged lithium batteries are initially shredded. The shredded lithium batteries are sent to the battery crusher for re-crushing, and then sent to the linear vibrating screen for preliminary screening. In this process, the black powder is initially collected.

3.Sieving and separation

The crushed materials are screened through screening machines to separate metal materials and positive and negative electrode powders. The scraps that do not meet the specifications are screened out by the linear vibrating screen and sent to crusher for crushing. The crushed lithium battery scraps are sent to the grinder for grinding, and then sent to eddy-vibrating screen for further sorting .

Sieving and separation

Sieving and separation

4.Metal separation

The screened metal materials are further separated through a magnetic separator and an airflow separator to obtain copper, aluminum and iron.

Advantages of DOING lithium battery recycling machine:

1.Pure physical sorting without any pollution and no pressure on environmental protection.

2.Simple operation, labor saving, low operating cost, and good one-time sorting effect.

3.Special equipment with larger output can be specially customized according to customer needs.

4.Advanced technology, mature technology, reliable equipment, high-quality products, low investment, low consumption and high returns.

If you are interested in lithium battery recycling business, welcome to contact us for an inquiry and our sales manager will provide the more detailed information about lithium battery recycling machine.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.