WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

What is the profit of processing one tonne in lithium battery recycling machine?

August 8, 2024

August 8, 2024- FAQ

- Leave a message

- Chat online

The profitability of processing one ton of lithium-ion batteries using a lithium battery recycling machine depends on several factors, including the efficiency of the recycling process, the market value of the recovered materials, operating costs, and the initial investment in the recycling technology. Providing exact numbers is challenging due to these variables, and this article aims to explore the profitability potential of operating a lithium battery recycling machine that processes one ton of lithium batteries.

Factors that influence profitability:

1. Material Recovery Rate:

The efficiency of extracting valuable metals during the recycling process is critical. Higher recycling rates directly mean more material to sell, leading to higher profits. Advanced recycling technologies can achieve recovery rates of up to 95% for some metals.

Lithium battery recycling machine

Lithium battery recycling machine

As a professional manufacturer with more than 14 years of experience, Henan DOING lithium battery recycling machine integrates crushing, carbonization, screening, conveying and other technologies to efficiently recover copper, aluminum and black mass from waste lithium batteries.

2. Market Prices:

Lithium batteries contain valuable metals such as lithium, cobalt, nickel, manganese, copper, aluminum, and graphite, and their recycling prices fluctuate with global supply and demand dynamics. The market outlook for these metals, driven by the growth in electric vehicle production, is positive and can significantly improve the profitability of recycling.

3. Operation Costs:

Operating a lithium battery recycling machine involves multiple costs, including capital expenditures for equipment, operating expenses such as electricity and labor, and environmental compliance costs. Advanced lithium battery recycling machine can automate and streamline processes and reduce labor costs, but requires a large upfront capital investment. The initial investment to establish a lithium battery recycling plant depends on the scale and technology used. In addition, complying with environmental regulations adds another layer of costs, including costs for permits, waste management fees, etc.

Lithium battery recycling machine

Lithium battery recycling machine

DOING can manufacture lithium battery recycling machines ranging from 500kg/h to 2t/h. In addition, DOING can also provide a full range of services including program formulation, equipment configuration, lithium battery recycling machine supply and installation according to customer needs.

4. Technology And Efficiency:

The choice of recycling technology will affect the operating efficiency and material purity. The technology of DOING lithium battery recycling machine mainly includes the following aspects:

Multiple crushing system: This system can continuously crush waste lithium batteries for subsequent sorting, improving processing efficiency and safety.

Pyrolysis system: Through pyrolysis technology, the organic matter in waste lithium battery materials can be decomposed into gas and liquid, realizing the effective recycling of resources.

De-powdering and screening system: This system can separate the powder in waste lithium battery materials, improving the purity and recovery rate of the materials.

Intelligent control system: Through the intelligent control system, the entire recycling process can be accurately controlled and optimized, improving production efficiency and product quality.

Lithium battery recycling machine

Lithium battery recycling machine

The application of these advanced technologies in DOING lithium battery recycling machines can not only improve the recycling efficiency and quality of waste lithium battery materials, but also reduce recycling costs and environmental pollution, which has important economic and social significance.

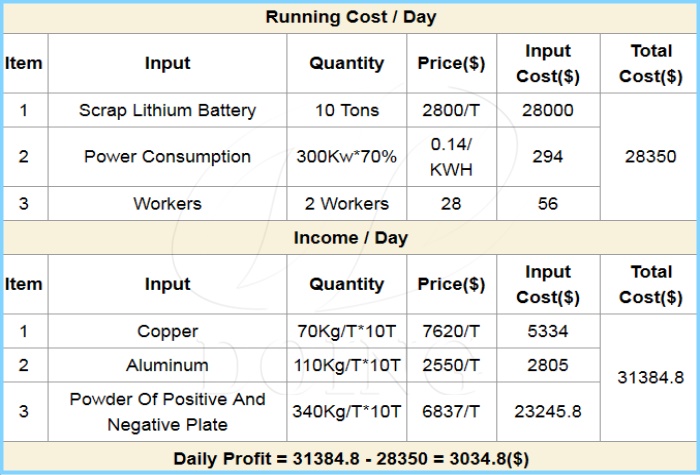

Profit Calculation:

To calculate profit potential, we must consider the revenue generated from the sale of recycled materials and the total costs involved. It is important to note that this is a highly simplified calculation and actual profits can vary greatly depending on the specifics of each business. This is the profit analysis we did before, which can give you a reference.

Profit analysis

Profit analysis

Welcome to contact us or leave a message to us to learn more about lithium battery recycling machine.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.