WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

What materials can be recovered from waste lithium batteries?

August 12, 2024

August 12, 2024- FAQ

- Leave a message

- Chat online

With the popularity of electric vehicles and renewable energy storage systems, the demand for lithium batteries has risen sharply, and the recycling of waste lithium batteries has become increasingly prominent. Waste lithium batteries are not simply waste, they contain valuable resources. This article will introduce you to the materials that can be recycled from waste lithium batteries, as well as environmentally friendly and efficient lithium battery recycling technology.

Waste lithium batteries

Waste lithium batteries

The materials that can be recycled from waste lithium batteries:

1. Nickel, cobalt, and manganese: These metals are the main components of battery positive electrode materials and have high economic value.

2. Lithium: As a key component of batteries, the recycling of lithium is crucial to battery manufacturing and energy storage industries.

3. Copper and aluminum: Used as conductive current collectors for batteries, they can be recycled and reused in battery production or other industrial purposes.

4. Graphite: Battery negative electrode material, which can be recycled for the manufacture of batteries or carbon-based materials.

5. Separator and electrolyte: Although recycling is difficult, these materials are gradually included in the scope of recycling through technological advances.

How to obtain these substances by processing lithium batteries through environmentally friendly and efficient recycling methods?

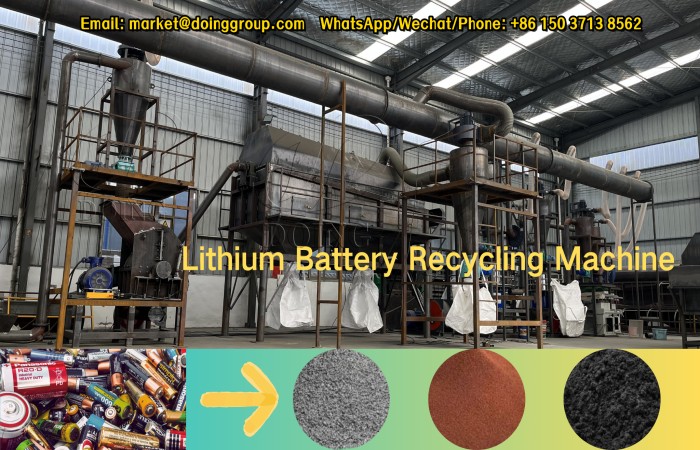

Traditional recycling methods often require the use of a large amount of chemical reagents, which not only pollutes the environment, but also increases recycling costs. In addition, there are problems such as low recycling rate and poor recycling quality. In order to solve the problems of traditional recycling methods, Henan DOING Machinery has developed a new process for green and efficient lithium battery recycling and processing equipment - lithium battery recycling machine.

The waste lithium battery recycling and processing machine is an important environmental protection equipment. It can effectively process various waste batteries, separate copper, aluminum, black powder and diaphragm, and achieve efficient recycling of valuable metals. Next, let's take a look at how the lithium battery recycling machine works.

The working process of the lithium battery recycling machine:

Lithium battery recycling machine

Lithium battery recycling machine

Step 1: soak the waste lithium battery in salt water to short-circuit the positive and negative poles of the battery, thereby releasing excess battery energy.

Step 2: send the discharged lithium battery to the shredder and crusher to process it into small particles.

Step 3: carbonization. Organic matter is converted into carbon-like substances by heating the battery residue in a low-oxygen environment. This process can remove the diaphragm of the lithium battery. If you need to collect the diaphragm of the lithium battery, DOING can also equip the linear screening to select the diaphragm of the lithium battery according to your needs.

Step 4: use the drum screening to select the black powder. Most manufacturers on the market are equipped with linear screens, which not only have a small output, but also have unclean screening. DOING is equipped with a drum screen with a sorting rate of up to 80%.

Step 5: The crushed fragments of the lithium battery enter the magnetic separator, and the iron is separated by magnetic attraction. The remaining materials are turned into powder by the mill and then enter the separation equipment such as the circular vibrating screen, airflow specific gravity separator, etc., which use the difference in material size and weight to efficiently separate copper, aluminum and black substances.

Lithium battery recycling machine

Lithium battery recycling machine

Henan DOING lithium battery recycling process uses physical methods for recycling, without the use of chemical reagents, so it will not cause pollution to the environment. The equipment can effectively remove impurities such as diaphragms, electrolytes, binders, etc., and the recycling efficiency can reach 99%, with high recycling quality. If you want to buy our lithium battery recycling machine, please leave a message below.

Contact Us

- Email:

- Tel/WhatsApp:

News

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.