WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

What is the recycling technology for lithium-ion batteries?

April 2, 2024

April 2, 2024- FAQ

- Leave a message

- Chat online

Usually, the proportions of cobalt, lithium, and nickel in used lithium-ion batteries are 5% to 15%, 2% to 7%, and 0.5% to 2% respectively. In addition, used lithium-ion batteries also contain metal elements such as copper, aluminum, and iron. Cobalt, in particular, is very rare and expensive. Random discarding not only pollutes the environment, but also wastes resources.

In order to solve the pollution and waste utilization problems of used lithium batteries and form a "production-recycling-reproduction" cycle chain, recycling technology emerged as the times require and has become a sustainable solution for recovering valuable materials from used lithium-ion batteries.

Recycling used lithium-ion batteries has significant environmental benefits and objective economic benefits. This article explores the recycling technologies and equipment involved in the process.

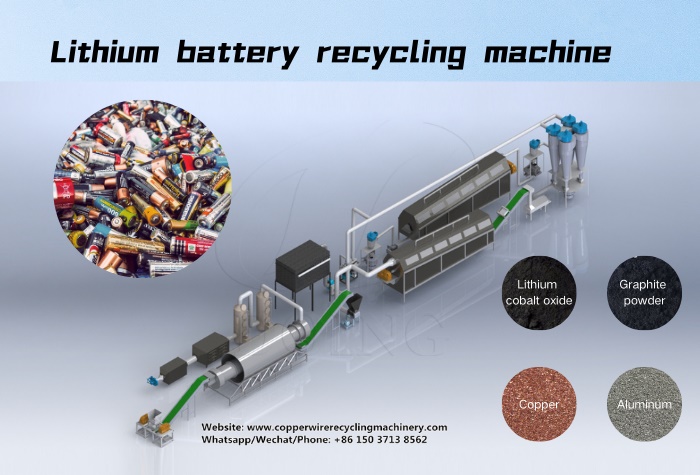

Lithium-ion battery recycling machine

Lithium-ion battery recycling machine

Lithium-ion battery recycling machine utilizes a variety of specialized equipment and technologies, including shredder, crusher, carbanization furnace, magnetic separators, grinder, air and electrostatic separators, vibrating screen, and dust collect system and gas cleaning system. The following are the specialized equipment and recycling technologies of lithium-ion batteries recycling machine.

1.Discharge: Put the used lithium-ion battery into 8%-15% NaCl solution to completely discharge the battery.

2.Shredder: Belt conveyor can transport scrap lithium battery to double shaft shredder to preprocess. After processing, 2-5cm used lithium-ion battery fragments can be obtained.

3.Carbanization furnace: The carbonization furnace uses electric heating or gas heating, and the heating temperature in the furnace is 100-450°C. Completely evaporate the electrolyte in the battery.

Carbanization furnace

Carbanization furnace

4.Dust and Gas Cleaning System: The gas purification system is mainly composed of a spray tower system, an activated carbon system and a UV photooxygen catalytic system. It can not only filter out most of the dust contained in the exhaust gas, but also process a variety of mixed exhaust gases to meet the emission standards.

5.Crusher and Grinder: Further crush the material to make it easier to separate.

6.Magnetic Separator: Iron can be separated from the raw material using a magnetic separator.

7.Separation: Black powder, copper and aluminum are separated through sorting equipment such as vibrating screens, magnetic separators, air separator, etc.

Lithium-ion batteries such as soft pack batteries, mobile phone batteries, shell batteries, cylindrical batteries, etc. can be recycled by Doing lithium-ion battery recycling machine. The crushing, sorting and recycling process is a key environmental protection technology for lithium battery recycling machine, which can effectively recover and utilize valuable materials in used lithium-ion batteries. The final products recycled by lithium-ion battery recycling machine are aluminum and copper, diaphragm and black mass. The entire process operates under negative pressure, with no dust and low dust, and the separation efficiency can reach more than 98%.

Final products

Final products

The lithium-ion battery recycling machine integrates advanced automation and control systems to ensure efficient and safe operation. The recycled materials can be further processed and refined to obtain high-purity recycled materials. These recycled materials can be used to produce new batteries or other applications, reducing reliance on raw materials and realizing resource recycling.

The rapid development of industries such as digital products and electric vehicles has produced a large amount of used lithium-ion batteries. Henan Doing's lithium-ion battery recycling machine separates and purifies metals and non-metals in used lithium-ion batteries, which has good market development prospects. If you have any questions about lithium-ion battery recycling machine, you can contact us at any time for consultation.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.