WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Which is better, the copper wire recycling machine or the wire stripping machine?

July 13, 2023

July 13, 2023- FAQ

- Leave a message

- Chat online

When it comes to recycling waste wires, there are two main machines that are commonly used: the copper wire recycling machine and the wire stripping machine. Both machines separate copper from waste wires, but they have different processing modes, different types of disposal of waste wires, and processing capabilities. Let's explore the differences between these two machines and determine which one is better.

1.Different processing modes

The wire stripping machine is designed to strip the insulation off the wire, leaving the copper core intact. The machine typically consists of a motor, a cutting blade, and a feed roller. The wire is manually fed into the machine, and the cutting blade strips off the insulation as the wire passes through. The separated copper is a piece of copper wire about the same length as the processed wire.

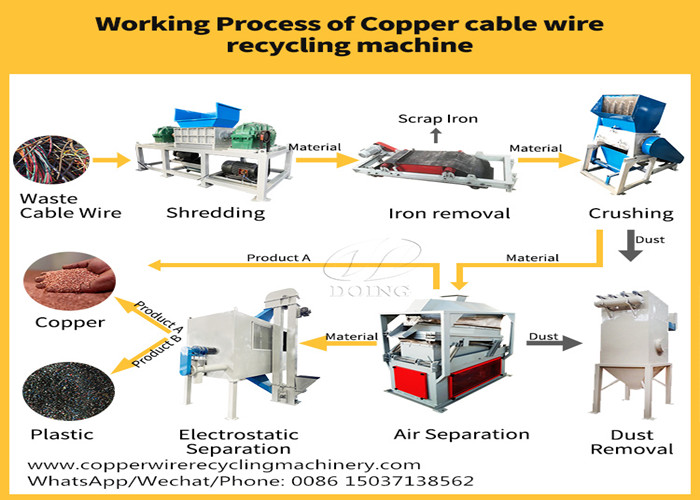

The copper wire recycling machine adapts blade crushing and physical sorting to process waste wires into copper and plastic. The configuration is not fixed, which can be adjusted according to your requirements and budget. The specific processing procedures are as follows.

Copper wire recycling machhine

Copper wire recycling machhine

The first step in the copper wire recycling process is to feed waste wires into the shredder, which breaks waste wires into smaller pieces. The shredded wires are then fed into the crusher, where they are further reduced in size. The crushed wire is then passed through an air separator, which separates the copper from plastic based on their different gravity. Finally, the separated plastic is sent through an electrostatic separator, which uses the different conductivity of copper and plastic to further separate the copper from the remaining plastic. The separated copper looks like rice, around 2-3mm.

Working process of copper wire recycling machine

Working process of copper wire recycling machine

Compared to the processing line of the copper stripping machine, the copper wire recycling machine is more complex. However, it is very easy to operate. The quality of the separated copper is the same, just a different length.

2.Different types of disposal of waste wires

| The type of wires | The diameter range of wires | |

| Copper wire recycling machine | thin miscellaneous wire, network cables, copper wires, data wires, square wires, home appliance plug wires, car wires, motorcycle electric lines, computer lines, communication cables, electric wires, household cable wires, and industrial cables, etc. | 1-90mm |

| Copper stripping machine | square wires, car wires, motorcycle electric lines, household cable wires, industrial cables, etc. | 12-65mm |

From this chart, we can find that the copper wire recycling machine is more versatile. It can handle a wide range of wire sizes, from thin headphone wires to thick industrial cables, and is more suitable for recycling various types of waste wire. What's more, the copper wire recycling machine can deal with tangled wires and recycle the copper of plugs of wires. But the copper stripping machine can't do that. Considering this, the copper wire recycling machine can recycle more copper and reduce the loss.

3.Different processing capacity

The wire stripping machine is suitable for smaller-scale recycling operations or for individuals who have a smaller volume of waste wire to process. In terms of a larger volume of waste wires, the copper wire recycling machine is a more advanced and efficient machine compared to the wire stripping machine. Besides, labor is getting more expensive now, and the copper wire recycling machine with PLC control system just needs one or two workers.

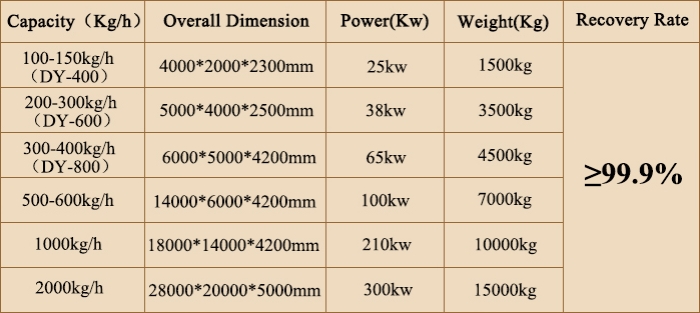

The capacity of the wire stripping machine is limited. But the copper wire recycling machine has different processing capacities for you to choose from, such as 100-150kg/h, 200-300kg/h, 400-500kg/h, 500-700kg/h, 800-1000kg/h, 1.5-2t/h. You can choose the proper model of the copper wire recycling machine according to the quantity of your waste wires.

The capacity of copper wire recycling machine

The capacity of copper wire recycling machine

In short, if the amount of waste wire is large and the types are complex, the copper wire recycling machine is better. At the same time, the copper wire recycling machine can meet the requirements of expanding business scale in the future. Henan Doing Company specializes in waste recycling machines for more than twelve years, and we have our own highly qualified engineering team. We can customize a suitable copper wire recycling machine for you to maximize your benefits.

If you are interested and want to know more details about the copper wire recycling machine, please contact us, and we are committed to offering you our best support.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.