WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How to recycle waste wires for profit? Which waste wires recycling way is recommended?

July 17, 2023

July 17, 2023- FAQ

- Leave a message

- Chat online

Recycling waste wires for profit is not only an environmentally friendly practice but also a lucrative business opportunity. As the demand for copper rises, it has become a viable option for individuals and businesses. In this passage, we will explore different recycling ways and recommend the most effective way to maximize profits.

Manual stripping is a common way to recycle waste wires by separating the metal from the plastic coating through careful cutting and peeling. However, it is not recommended for large quantities due to inefficiency.

Another popular method for recycling waste wires is mechanical stripping. This process involves the use of copper stripping machine to strip the insulation from the wires. Compare with manual stripping, this way not only increases productivity but also ensures a higher quality of metal extraction, resulting in better profits.

Copper wire recycling granulator

Copper wire recycling granulator

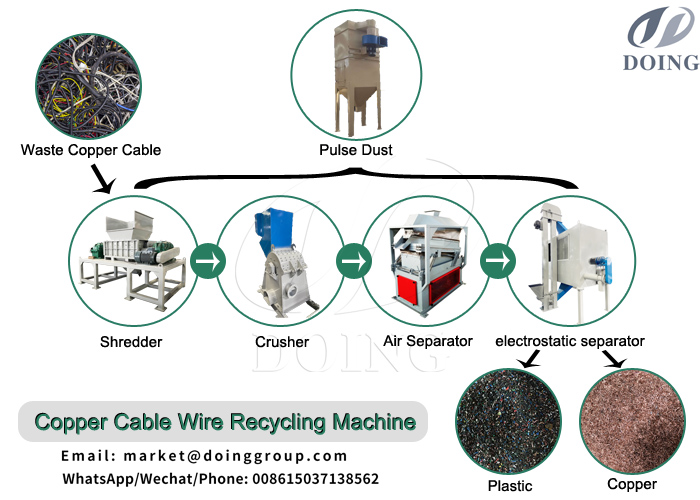

In recent years, a more advanced way of recycling waste wires has gained popularity -- the use of copper wire recycling granulator. Copper wire recycling granulator is a machines that shred and crush waste wires into smaller pieces, making it easier to separate. These smaller pieces will separated by air separator or electrostatic separator, or both of these separators. Copper wire recycling granulation is highly effective for processing large quantities of waste wires.

The capacity of copper wire recycling granulator

The capacity of copper wire recycling granulator

In order to meet different requirements of clients from different regions, Henan DOING designs different processing capacity. Our machine has different processing capacities for you to choose from, ranging from 200-300kg/h to 1t/h. If you really don’t know how to choose, we have professional salesmen who can provide a suitable scheme according to your raw materials.

When it comes to choosing the recommended way to recycle waste wires for profit, it is essential to consider several factors. Firstly, the scale of the operation plays a crucial role. For small-scale operations or occasional recycling, manual stripping or copper stripping machines may be sufficient. However, for larger quantities of waste wires, investing in more advanced machinery such as copper wire recycling granulator is highly recommended.

Different types of wires and cables

Different types of wires and cables

Additionally, it is important to consider the types and quality of the waste wires being recycled. Different wires have varying metal content and insulation types, which can affect the separation rate of copper separated and profitability of the recycling process.

The configuration of copper wire recycling granulator is commonly consist of a shredder, a crusher, air separator, a electrostatic separator and a pulse dust collector, which can deal with almost waste wires. If you worry about the separation rate, our engineer could adjust the configuration to reduce the lost and increase the quantity copper separated.

The configuration of copper wire recycling granulator

The configuration of copper wire recycling granulator

Having specialized in waste recycling machines for over twelve years, Henan Doing Company boasts a team of highly qualified engineers. We adapts the technology of gravity and conductivity, the copper wire recycling granulator can reach 99% separation rate. By the way, with PLC control system, the automatic degree of this machine is relatively high and just need one or two workers to operate. Although copper wire recycling granulator require a higher initial investment, we offer better efficiency and copper recovery rates, leading to increased profits.

Furthermore, staying updated with market trends and metal prices is essential for maximizing profits. The value of metals such as copper fluctuates regularly, and being aware of these fluctuations can help in timing the recycling process to achieve the highest possible returns.

Waste wires have the potential to generate a significant income if you are willing to invest your efforts. If you are intrigued and would like to obtain further information, please do not hesitate to get in touch with us.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.