WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Biomass pyrolysis carbonization furnace

We provide free trial service.

You can also visit our factory.

- Tel: +86 371 5677 1821

- WhatsApp: +86 150 3713 8562

- Phone: +86 150 3713 8562

- Email: market@doinggroup.com

Biomass pyrolysis carbonization furnace is also known as charcoal making machine, which can recycle various biomass wastes and make high-quality charcoal. Henan DOING biomass pyrolysis carbonization furnace combines pyrolysis technology with high efficiency and good quality.

Biomass pyrolysis carbonization furnace

Biomass pyrolysis carbonization furnace

The raw materials that can be processed by the biomass pyrolysis carbonization furnace:

1. Various biomass: such as sawdust, coconut shells, olive shells, palm shells, corn cobs, straw, bamboo, wood chips, wood, etc.;

2. Sludge: urban sludge, municipal sludge, industrial sludge, etc.;

3. Garbage: urban domestic waste, electronic waste, solid waste, etc.

Raw materials

Raw materials

The processing capacity of the charcoal making machine for sale:

| Hot Sale Carbonization Machine | ||

| Model | Capacity | Reactor Size |

| DY-T-1 | 1T/H | Ф1300mm*14000mm |

| DY-T-2 | 2T/H | Ф1600mm*14000mm |

| DY-T-3 | 3T/H | Ф1800mm*14000mm |

(Tips: Our engineers can customize carbonization machine that better suits your needs based on your raw materials and requirements.)

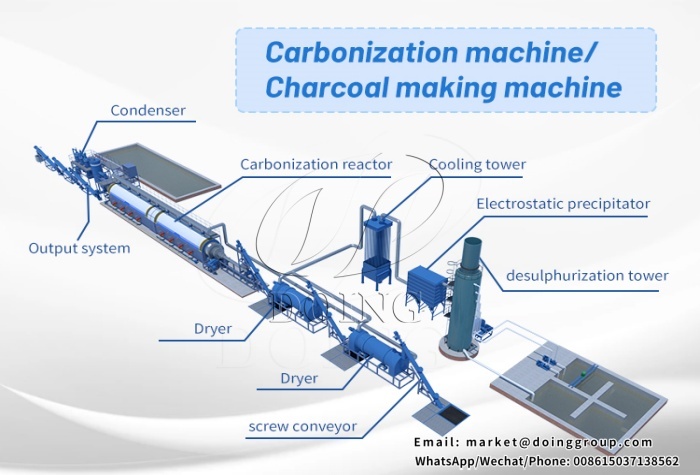

How does the biomass pyrolysis carbonization furnace work?

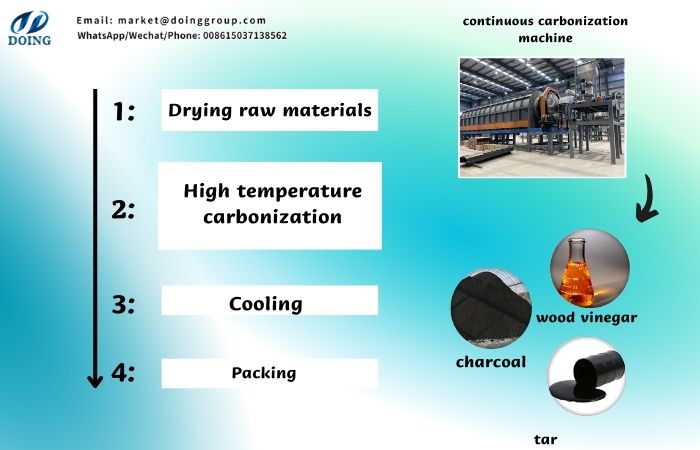

The charcoal making process of the biomass pyrolysis carbonization furnace mainly includes three conversions: 1. Biomass is converted into charcoal; 2. Organic matter is converted into combustible gas; 3. Compounds are converted into wood vinegar and wood tar. The following are the specific steps of the charcoal making machine:

Biomass pyrolysis carbonization furnace

Biomass pyrolysis carbonization furnace

Pretreatment:

Determine whether it needs to be crushed and dried according to the particle size and moisture of the raw materials. It is recommended that the moisture content of the raw materials is less than 15% and the particle size is within 30mm. If drying is required, the raw materials need to be sent to the drum dryer and then to the biomass pyrolysis carbonization furnace for high-temperature carbonization.

Pyrolysis carbonization:

The pretreated raw materials enter the preheated biomass pyrolysis carbonization furnace through a belt conveyor. The reaction is carried out in a high-temperature micro-oxygen environment (400℃~600℃). The raw materials are removed from the internal moisture and organic volatiles in the furnace, and finally form charcoal with a high carbon content. The products produced by the carbonization process are combustible gas, wood vinegar, tar, and charcoal.

Utilization of combustible gas:

The gas generated by the biomass pyrolysis carbonization furnace is directly transported to the burner for combustion. A part of it is burned and catalyzed, and the remaining gas is heated to continue to provide heat for the carbonization furnace and drying furnace. After that, these gases are filtered and cooled and discharged through the chimney.

Charcoal Collection:

The high-temperature charcoal coming out of the biomass pyrolysis carbonization furnace enters the discharging system. The water cooling system exchanges heat with the high-temperature charcoal through cooling water to reduce the charcoal discharge temperature, and finally collects and stores the charcoal.

Steps of the charcoal making machine

Steps of the charcoal making machine

Products and Applications of Biomass Pyrolysis Carbonization Furnace

Charcoal can be used as an efficient fuel in various heating and processing processes, and is widely used for heating, barbecue and cooking. In addition, it can also be used as a building material, anode material for batteries, feed additives, etc. Wood vinegar can be used as a pesticide and deodorant. Wood tar can be used to make anti-corrosion coatings, or to produce various chemical products such as phenolic compounds, asphalt, dyes, etc.

Products

Products

Advantages of DOING Biomass Pyrolysis Carbonization Furnace

1. Continuous operation without shutdown: The biomass pyrolysis carbonization furnace can work continuously for 24 hours without stopping.

2. Safety guarantee: DOING carbonization equipment is equipped with multiple safety devices to ensure the safe operation of the equipment, including emergency pressure relief devices, explosion-proof devices related to pressure sensors, and anti-leakage devices such as sealing rings and valves, as well as PLC system intelligent control systems, alarm devices, etc.

3. Greatly save fuel costs: The combustible gas generated by the charcoal making machine can be recycled to provide heat energy for the reactor. Choosing Henan DOING machines can save a lot of fuel costs.

4. Environmentally friendly design: Henan DOING biomass pyrolysis carbonization furnace has a dust removal system and a cooling system, which is an ideal equipment for environmental protection and pollution-free.

Biomass pyrolysis carbonization furnace

Biomass pyrolysis carbonization furnace

Services we provide:

1. 24-hour online service. Call us at any time to ask questions.

2. Provide installation services or online technical support.

3. Monitor the transportation links throughout the process to ensure safety and timeliness.

At present, energy shortages are common. How to convert more waste into usable resources is a matter of concern. The biomass pyrolysis carbonization furnace manufactured by Henan DOING solves this problem well and will bring benefits to customers. We provide a series of services to guarantee the rights of customers. If you are interested in our biomass pyrolysis carbonization furnace, please contact us immediately to get a price list.

News

Indian customer ordered DOING 100-150kg/h circuit board recycling machine

DOING 100-150kg/h PCB Recycling Machine Shipped to Zambia, Powering Local E-Waste Automation

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.