WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Carbonization Equipment

We provide free trial service.

You can also visit our factory.

- Tel: +86 371 5677 1821

- WhatsApp: +86 150 3713 8562

- Phone: +86 150 3713 8562

- Email: market@doinggroup.com

DOING carbonization equipment consists of multiple parts including feeding system, dryer, carbonization chamber, cooling system, exhaust system, control system, etc. It can efficiently convert biomass waste into high-quality charcoal, combustible gas and tar through pretreatment, drying, carbonization, cooling and other processes.

Processing materials of DOING carbonization equipment:

Carbonization equipment can be applied to many types of biomass materials, including but not limited to agricultural residues (such as straw, corn stalks), forestry by-products (such as branches, bark), and urban organic waste (such as kitchen waste, peels). These materials, originally considered "garbage", can not only reduce environmental pollution problems after proper treatment, but can also be converted into valuable resources - biochar or charcoal.

Raw materials

Raw materials

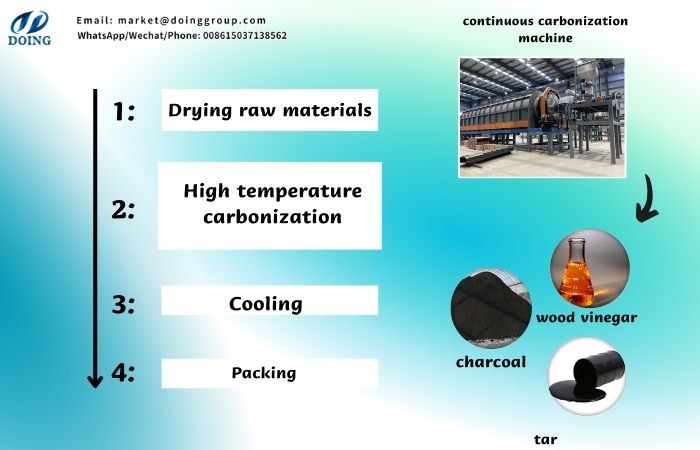

Working process of DOING carbonization equioment:

Generally, the working process of DOING carbonization equipment mainly includes pretreatment, drying, carbonization, cooling steps, as follows:

1.Pretreatment:

In the process of carbonization equipment, pretreatment is the first step. For the collected raw materials, preliminary processing operations such as screening and crushing must be carried out. The purpose is to remove impurities from the raw materials and adjust their size to the ideal state suitable for entering the carbonization furnace.

2.Drying:

Through drying, the water in the material can be volatilized, so that a large amount of heat is not required to evaporate and volatilize the water during carbonization, thereby reducing energy consumption during the carbonization process. At the same time, drying can effectively improve the quality of carbonization, ensure the quality and stability of carbonization, and prevent cracking or even explosion after carbonization.

3.Carbonization:

When the temperature reaches a certain level, the volatile organic matter in the raw materials begins to decompose, producing some combustible gases (such as methane, carbon monoxide, etc.), and the solid part of the raw materials begins to carbonize, eventually forming carbonaceous solid fuels such as charcoal. In this process, it is necessary to pay attention to controlling parameters such as temperature and carbonization speed to ensure the quality of the carbonized product. It is worth mentioning that these combustible gases have the potential to be used as fuel and can be used for drying or carbonization process.

4.Cooling

After the carbonization process is complete, the material must be gradually cooled to avoid cracking or structural damage. After sufficient cooling, the carbonized material is discharged from the chamber.

Working process of DOING carbonization equioment

Working process of DOING carbonization equioment

Final products and value:

Main products: Charcoal is a high-quality fuel source with high energy density and low ash content. It can also be used as a soil conditioner, which helps to improve soil fertility and retain moisture.

Added value: In addition to the main product, the carbonization process also produces by-products such as combustible gas and tar. The former can be used for power generation or as a clean fuel supply; the latter can be further refined to extract various chemical raw materials, increasing the economic benefits of the overall project.

Products and applications

Products and applications

Equipment advantages of DOING carbonization equipment:

1. Energy saving and environmental protection: The closed design effectively avoids air pollution problems; at the same time, it is also equipped with a waste heat recovery system, which greatly improves energy utilization.

2. Easy operation: The high degree of automation reduces labor costs while ensuring production efficiency.

3. Strong adaptability: The design scheme can be flexibly adjusted according to different needs such as raw materials, capacity, etc. to meet diverse market demands.

Over the past 14 years, DOING's engineers and sales team have been committed to providing customers with a full range of services, including customized solutions, detailed quotations, technical guidance and training, etc. So, if you want to get more information about our carbonization equipment, please contact us.

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.