WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Horizontal pyrolysis carbonization machine

We provide free trial service.

You can also visit our factory.

- Tel: +86 371 5677 1821

- WhatsApp: +86 150 3713 8562

- Phone: +86 150 3713 8562

- Email: market@doinggroup.com

The horizontal pyrolysis carbonization machine uses advanced pyrolysis technology to turn various biomass into charcoal and other by-products. Henan DOING horizontal pyrolysis carbonization machine is an ideal carbonization equipment, with smokeless and pollution-free production process.

Horizontal pyrolysis carbonization machine

Horizontal pyrolysis carbonization machine

Introduction to horizontal pyrolysis carbonization machine

With the development of society, environmental pollution problems have become more and more serious, especially the recycling of biomass raw materials and waste materials in production, harmful soil, etc. is seriously insufficient, resulting in a great waste of resources and environmental pollution. In response to the call to turn agricultural straw and other biomass raw materials into treasure, Henan DOING Company has joined forces with mechanical professionals to study and finally developed a new horizontal pyrolysis carbonization machine. This horizontal pyrolysis carbonization machine is a new type of carbonization machine that feeds raw materials on one side and outputs finished charcoal on the other side, with a processing capacity of 1T/h-3T/h.

DOING horizontal pyrolysis carbonization machine has a wide range of uses. Applicable raw materials include: peanut shells, sawn wood, corn stalks, bagasse, branches, rice husks, bamboo chips, sorghum stalks, sunflower seed shells, distiller's grains, corn cobs, sorghum stalks, coconut shells, coffee grounds, cotton stalks, bean stalks, yam grass, dead leaves and other biomass raw materials; waste pharmaceutical factory scraps; pharmaceutical residues; sludge, etc. Horizontal pyrolysis carbonization machine is the best choice to alleviate the tension between supply and demand of resources and turn waste into treasure.

Horizontal pyrolysis carbonization machine raw materials

Horizontal pyrolysis carbonization machine raw materials

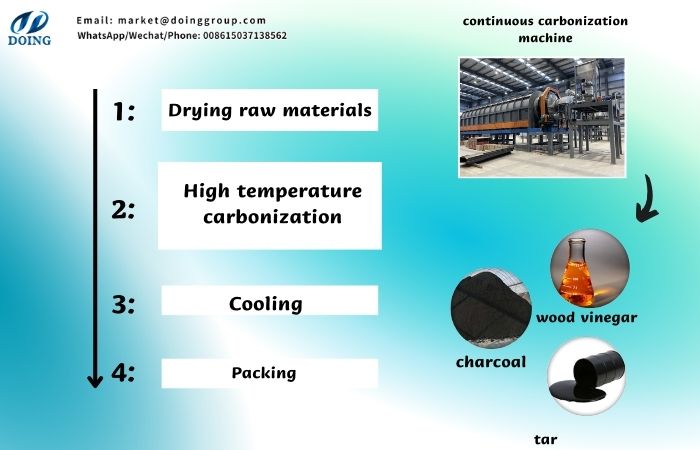

Horizontal pyrolysis carbonization machine process

Horizontal pyrolysis carbonization machine can run 24 hours a day, and charcoal can be produced in about half an hour. It can be fed and charcoal can be produced at the same time. The whole process is highly automated, efficient and stable. The following is the 3d working process video and specific introduction of horizontal pyrolysis carbonization machine.

1. According to the particle size and moisture of the material, determine whether the material needs to be crushed and dried. If crushing is required, the material will be crushed into particles below 30mm to ensure the carbonization effect; if drying is required, the material will be transported to the drum dryer to dry until the moisture content is below 15%, and then transported to the pyrolysis carbonization furnace for carbonization to reduce the load of the carbonization furnace;

2. Use external heat sources such as burners to heat the pyrolysis carbonization main furnace. The material is dried, dehydrated, and carbonized in the carbonization furnace. When the material is heated to a certain temperature, it begins to produce combustible gas. After purification and separation, the combustible gas is sent to the combustion chamber through the induced draft fan for high-temperature combustion extinguishing treatment; the hot gas after extinguishing continues to heat the carbonization main furnace, and the residual heat after heating the main furnace is introduced into the dryer to dry the material; the exhaust gas after drying is treated by cyclone dust removal and tail gas purification tower, and then sent to the chimney for discharge;

3. When combustible gas is generated, the burner can be gradually stopped until it is turned off, and then only the self-produced pyrolysis gas during the carbonization of the material is used for heating (if the pyrolysis gas of the material is insufficient, an external heat source needs to be added).

4. The finished product after carbonization is cooled and transported to make it fully cooled and then sent to the material yard or silo for packaging or storage. The cooling water of the cooling system can be recycled through the water pump after being cooled by the cooling tower.

Horizontal pyrolysis carbonization machine working process

Horizontal pyrolysis carbonization machine working process

Final products and uses:

The products of the horizontal pyrolysis carbonization machine during the carbonization process include solid charcoal, combustible gas, wood vinegar and tar, etc.

Charcoal: Charcoal can be used as fuel, with a higher calorific value than similar raw materials and a better combustion effect than ordinary coal blocks. Charcoal can also be used as a raw material in the industrial field to make activated carbon, purifiers, etc., and can also be used as an organic fertilizer to improve soil quality. Charcoal is easy to sell, has quick results, is widely used, and has a large market demand.

Wood vinegar: After refining, it can be used to keep food fresh, or it can be directly sprayed on the soil for disinfection or deodorization in places with odor.

Tar: It can be used as fuel or made into fireproof materials after processing.

Combustible gas: It is used as fuel for furnace combustion.

Final products and uses

Final products and uses

Advantages of DOING horizontal pyrolysis carbonization machine for sale

1. Excellent material: The carbonization main furnace adopts Q345R special boiler plate material, which has high strength, high temperature resistance and is not easy to deform.

2. High production efficiency: The traditional carbonization furnace burns one furnace and produces one furnace, and it takes a long time to cool down the carbonization; while DOING horizontal pyrolysis carbonization machine can feed and produce carbon at the same time, and carbonize continuously for 24 hours without stopping to cool down the carbonization, saving heat energy and time, and high production efficiency.

3. Heat energy recovery and reuse: The combustible gas produced by carbonization of materials can be recycled and used as fuel to heat the carbonization main furnace, without consuming additional fuel, improving the utilization rate of heat energy and achieving self-sufficiency.

4. Safety and environmental protection: The horizontal pyrolysis carbonization machine adopts an integrated sealing design to realize fully enclosed production operation, ensuring that the solid product is transported in the enclosed equipment and pipelines, without dust leakage and dust, and is equipped with environmental protection treatment devices, with a high safety and environmental protection coefficient.

Horizontal pyrolysis carbonization machine

Horizontal pyrolysis carbonization machine

Henan DOING Company specializes in manufacturing horizontal pyrolysis carbonization machines. We always pay attention to the needs of users and provide good products and services. If you are interested in high quality horizontal pyrolysis carbonization machine for sale at factory price, we can customize solutions for you. Welcome to visit DOING company!

PREV:Nothing

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.