WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

What are the full-line machines for aluminum plastic separation?

July 4, 2024

July 4, 2024- FAQ

- Leave a message

- Chat online

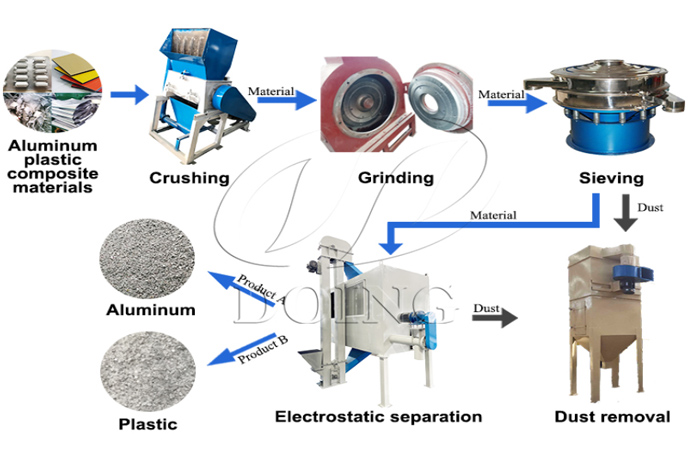

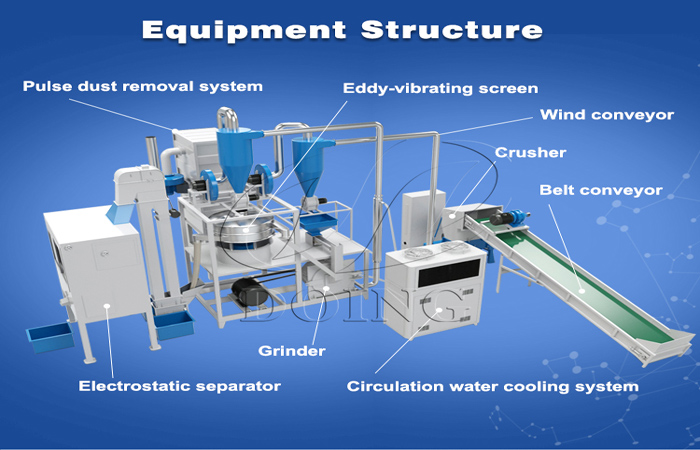

Aluminum plastic recycling equipment is suitable for various aluminum plastic composites such as waste aluminum-plastic, aluminum-plastic panels, tablet board, copper foil board, scraps, food packaging bags, etc. The whole set of aluminum plastic recycling equipment is composed of crushers, grinders, eddy-vibrating screen, electrostatic separators and pulse dust collectors. The aluminum-plastic separator adopts electrostatic separation technology, which is low in cost and high in efficiency, and the separation rate can reach 99%. Next, this article will introduce the functions and characteristics of each machine one by one.

Aluminum plastic recycling equipment

Aluminum plastic recycling equipment

Full line configuration of aluminum-plastic recycling equipment:

1. Crusher: The purpose of the crusher is to process aluminum-plastic materials into smaller particles. Crusher can be divided into three categories: hammer crusher, hammer slice crusher and blade crusher. After careful research and consideration, DOING engineers chose to equip blade crusher to process aluminum-plastic, because the material of blade crusher is SKD-11, and its high carbon content and high chromium content enable it to maintain excellent cutting performance under high temperature and high pressure environment, and it is not easy to deform and wear.

2. Grinding mill: used to grind aluminum-plastic crushed materials into powder with finer particles. There are three types of grinding mills designed by DOING. Customers can choose the appropriate grinding mill according to the different raw materials to be processed. Among them, the knife disc grinding mill is suitable for the processing of aluminum-plastic pharmaceutical plates, the grinding disc grinding mill is used for the processing of aluminum-plastic films and aluminum-plastic packaging materials, and the turbine grinding mill is suitable for the processing of aluminum-plastic plates. Since the grinding process will generate high temperature, DOING is equipped with a circulating water cooling device to cool down, and the plastic will not melt or discolor due to the temperature increase caused by the long-term operation of the equipment.

Grinding mill

Grinding mill

3. Eddy-vibrating screen: a high-precision fine powder screening machine that uses centrifugal force to generate vibration. The rotary vibration screen separates and classifies aluminum plastic powder on a rotating screen. It has the characteristics of small size, light weight, low noise and high efficiency. The eddy-vibrating screen designed by DOING has two layers of mesh. After the aluminum-plastic mixed powder enters, it will pass through two screenings. The material that does not meet the particle size requirements will remain on the screen and return to the grinding mill through rotation and vibration for further processing. After this step, the aluminum-plastic powder is already very fine and impurities have been removed.

4. Electrostatic separator: Considering the different electrical properties of aluminum and plastic, DOING chose to equip an electrostatic separator to separate aluminum and plastic in aluminum-plastic mixed powder. Electrostatic separator is a kind of equipment specially used for sorting metal and non-metal. Its working principle is to use the electric field force of materials in high-voltage electric field. Materials with different charges will be subject to electric field forces of different sizes and directions in the electric field, thus producing different motion trajectories. By reasonably setting the electric field strength and direction, fine sorting of materials can be achieved, with a sorting rate of up to 99%.

Aluminum plastic recycling equipment

Aluminum plastic recycling equipment

5. Pulse dust collector: The purpose of pulse dust collector is to remove dust during the operation of the equipment. It is a high-efficiency and low-energy dust removal equipment. It uses solenoid valves to control the work of compressed air, air bags and nozzles to make the filter bags expand rapidly, thereby shaking off the dust attached to the surface of the filter bags, collecting and treating dust exhaust gas. Compared with traditional gravity dust removal, water washing dust removal and cyclone dust removal, DOING pulse dust collector has the following advantages:

(1) High processing efficiency, can effectively remove tiny particles of dust;

(2) Low energy consumption, low power supply requirements;

(3) Small footprint, low installation, commissioning and maintenance costs.

Aluminum plastic recycling equipment

Aluminum plastic recycling equipment

DOING aluminum plastic separation equipment is a multi-machine combination structure, one-time feeding, multiple machines complete, and the machines are connected by automatic conveying devices. Aluminum plastic recycling equipment has the characteristics of low noise, high output and strong innovation. If you are interested in other related information about DOING aluminum plastic separation equipment, please feel free to contact us. You are welcome to call us for consultation. We will serve you wholeheartedly.

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.