WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Can solar panels be recycled?

April 17, 2025

April 17, 2025- FAQ

- Leave a message

- Chat online

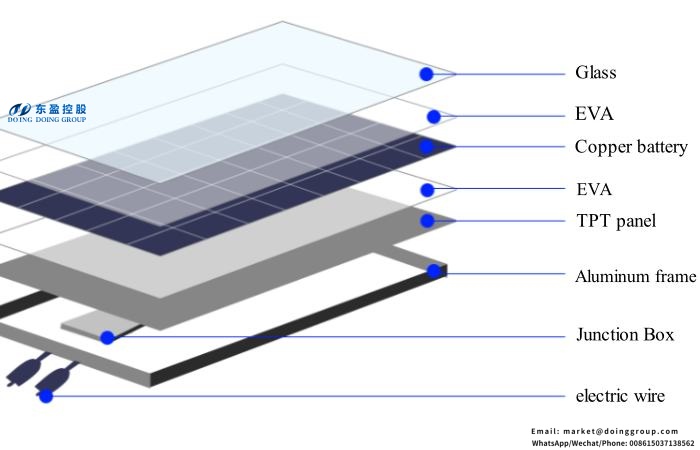

Solar panels are mainly composed of glass, aluminum frames, silicon materials and a small amount of precious metals. Each part has recycling value and can be recycled and reused. With the advancement of technology, more and more recycling methods have enabled the materials of solar panels to be effectively reused.

Solar panel composition

Solar panel composition

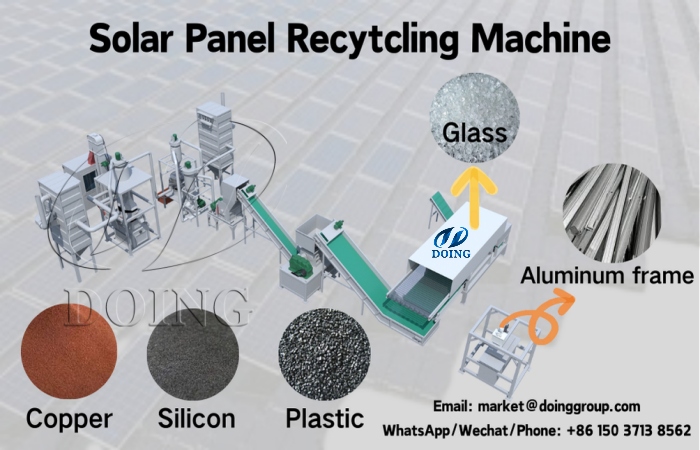

How are solar panels recycled?

Professional solar panel recycling machine can efficiently recycle solar panels and ensure that all kinds of materials are reasonably recycled. Next, I will introduce the specific recycling process of the solar panel recycling plant of DOING company:

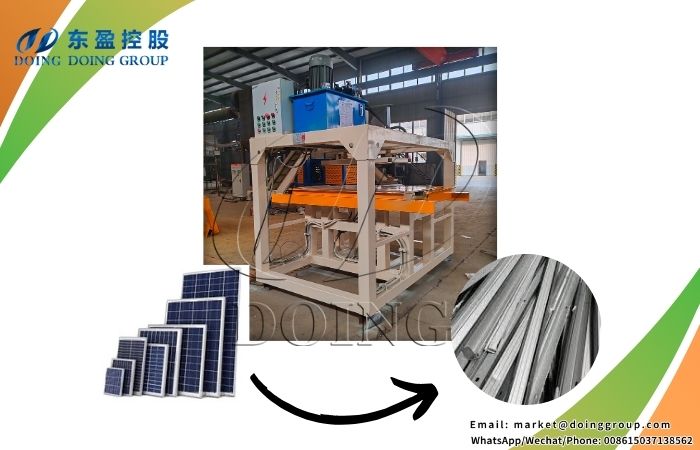

1. Aluminum frame recycling

Place the solar panel on the operating table of the aluminum frame dismantling machine, and use mechanical extrusion separation to remove the aluminum frame around the solar panel to obtain the aluminum frame.

DOING aluminum frame dismantling machine for solar panels recycling

DOING aluminum frame dismantling machine for solar panels recycling

It should be noted that there are many types of waste solar panels on the market, and the sizes are different. When purchasing, you need to pay attention to the applicability of the aluminum frame dismantling machine. Our aluminum frame dismantling machine can handle solar panels of all sizes on the market, with the advantages of high cost performance, simple operation and convenient maintenance.

2. Glass recycling

The solar panel after frame removal enters the glass removal machine, and is heated to 110-120 degrees at high temperature to soften the EVA glue and separate it from the glass. Subsequently, the crusher built into the glass removal machine accurately and efficiently crushes the glass, separates the glass from the solar cell, and finally obtains granular glass and intact solar cells.

Glass removal machine for solar panels processing

Glass removal machine for solar panels processing

DOING's glass removal machine uses pyrolysis separation technology to control the appropriate temperature and time to inactivate the adhesive between the solar panel and the glass, thereby effectively separating the two. This treatment method is popular because of its low damage to the material and high recovery rate.

3. Recycling of copper, silicon, plastic, etc.

The cell is first shredded by the belt conveyor, then crushed by the crusher, and then ground by the mill. The ground cell enters the rotary vibrating screen to screen out the silicon powder. The copper and plastic mixture in the middle layer of the rotary vibrating screen enters the next air flow separator to separate copper and plastic. Finally, the separated plastic enters the electrostatic separator for secondary selection to obtain copper with higher purity.

DOING solar panel recycling plant adopts physical crushing and sorting methods to achieve high-purity and high-recovery material recovery. Our equipment can achieve a recovery rate of more than 98%, with the advantages of high automation, easy operation, and large processing capacity, which can meet the needs of large-scale processing of waste solar panels.

DOING solar panel recycling plant for waste solar panels disposal

DOING solar panel recycling plant for waste solar panels disposal

Through this solar panels recycling method, these recycled materials not only have economic value, but also reduce the demand for new mining resources, realize resource recycling, provide raw materials for the manufacture of new solar panels, thereby reducing production costs, and also help environmental protection.

In order to help you recycle solar panels efficiently and safely, our DOING company provides professional solar panel recycling plant. Our equipment uses advanced technology to efficiently decompose the various materials in solar panels to ensure maximum resource recovery and environmental benefits. If you have any needs regarding solar panel recycling, please feel free to contact us and we will provide you with professional solutions.

Contact Us

- Email:

- Tel/WhatsApp:

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.