WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

What are the byproducts of biomass pyrolysis?

April 1, 2025

April 1, 2025- FAQ

- Leave a message

- Chat online

The byproducts of biomass pyrolysis primarily consist of three main forms: charcoal, bio-oil (also known as pyrolysis oil), and syngas (a mixture mainly comprising carbon monoxide, hydrogen, and methane) . Here's a more detailed look at each:

1. Charcoal Composition

Charcoal is the solid residue left over from the pyrolysis process. It contains mostly carbon but also retains some minerals originally present in the biomass. Depending on its quality and intended use, char can serve multiple purposes. High-quality char can be used as an activated carbon for water treatment or air purification. It is also used as a soil amendment (biochar) which can improve soil fertility and sequester carbon. Additionally, less refined forms of char can be used as a solid fuel.

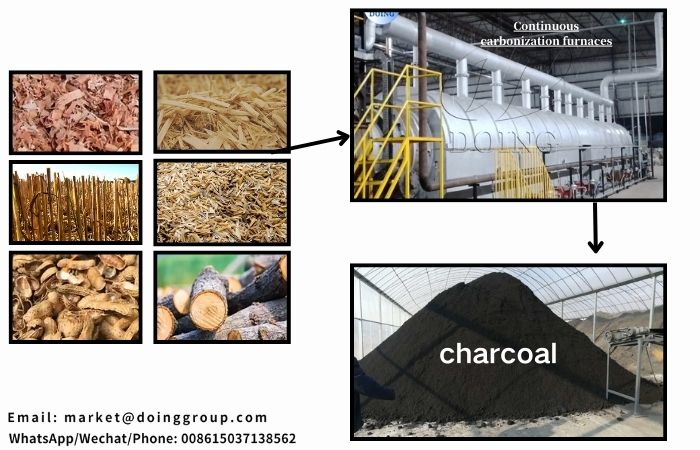

Biomass pyrolysis byproduct: charcoal

Biomass pyrolysis byproduct: charcoal

2. Bio-Oil Composition

Bio-oil is a complex mixture containing various organic compounds such as acids, alcohols, aldehydes, ketones, phenols, and other oxygenated hydrocarbons. It can be used directly as a fuel for boilers or engines after some upgrading, or further refined into higher quality fuels like biodiesel or green gasoline. Additionally, bio-oil has applications in the chemical industry as a source for producing specialty chemicals.

DOING biomass pyrolysis machine has an advanced temperature control system that can accurately adjust the temperature in the pyrolysis furnace during the entire reaction process according to different production needs to improve the purity and yield of bio-oil.

Temperature control system of DOING biomass pyrolysis machine

Temperature control system of DOING biomass pyrolysis machine

3. Syngas Composition

Syngas consists mainly of carbon monoxide, hydrogen, and smaller amounts of methane, along with traces of other gases like carbon dioxide and nitrogen depending on the process conditions. This gas mixture can be utilized for electricity generation, heat production, or as a feedstock in the synthesis of methanol, ammonia, and other chemicals. In some cases, it can also be upgraded to synthetic natural gas (SNG) or used in Fischer-Tropsch processes to produce liquid hydrocarbons.

Biomass pyrolysis machine 3D diagram

Biomass pyrolysis machine 3D diagram

DOING's biomass pyrolysis machine optimizes the purity of syngas by controlling the oxygen level. Our pyrolysis machine adopts a fully enclosed design, which can effectively control the pyrolysis environment and ensure that the pyrolysis reaction is carried out under stable conditions. By maximizing the control of oxygen content to an extremely low level (close to oxygen-free), the purity of the syngas is improved, and ultimately the ideal pyrolysis effect is achieved.

Each of these byproducts has distinct characteristics and uses, making biomass pyrolysis a versatile approach for converting waste biomass into valuable materials and energy carriers. Commonly speaking, the biomass pyrolysis final products yield ratios are usually: charcoal (30–35%), bio-oil (5–10%), syngas (25–35%). The quality and yield of pyrolysis byproducts depend largely on temperature, raw materials and equipment precision.

DOING biomass pyrolysis machine final products

DOING biomass pyrolysis machine final products

Choosing the right pyrolysis machine can achieve high yield and high quality byproducts. DOING provides customizable pyrolysis solutions to ensure high yield and high quality byproducts according to specific raw materials and different production requirements.

Features and advantages of DOING biomass pyrolysis machine:

1. Higher efficiency

DOING biomass pyrolysis machine adopts the method of continuous feeding by conveyor belt, which can operate around the clock and significantly increase the output. Our pyrolysis equipment can process 2-3 tons of raw materials per hour, and the daily processing capacity can reach 48-72 tons, which is very suitable for large-scale production to maximize production efficiency while reducing labor costs.

2. Comprehensive material processing

Raw materials that can be processed by DOING biomass pyrolysis machine

Raw materials that can be processed by DOING biomass pyrolysis machine

DOING pyrolysis machine is designed to process a variety of biomass raw materials, including various agricultural wastes, such as palm shells, wood, coconut shells, corn cobs, rice husks, straw, sawdust, bamboo, etc., as well as various sludge garbage and domestic garbage. The raw material flexibility makes DOING's equipment suitable for the recycling of various wastes and reduces production costs.

3. Energy-Saving & Eco-Friendly

DOING prioritizes environmental protection in the design of biomass pyrolysis machines. Our pyrolysis equipment has an advanced heat recovery system to reduce energy consumption and minimize emissions. In addition, the equipment is equipped with an efficient dust removal system and cooling system to avoid air pollution problems.

Choosing high-quality pyrolysis machine can get high-quality byproducts with high output yields. Welcome to consult our pyrolysis technology and customize solutions for your biomass conversion needs! In addition to providing high-quality machines, DOING also provides comprehensive technical support: installation and commissioning assistance, operator training, after-sales maintenance services, and more.

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.