WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

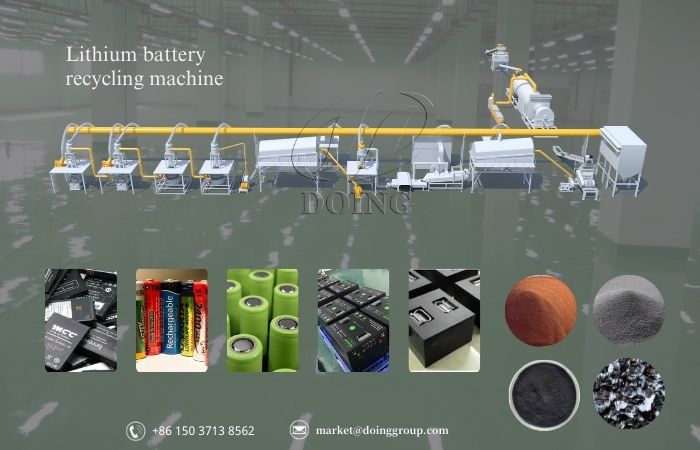

Cylindrical battery recycling machine

We provide free trial service.

You can also visit our factory.

- Tel: +86 371 5677 1821

- WhatsApp: +86 150 3713 8562

- Phone: +86 150 3713 8562

- Email: market@doinggroup.com

Cylindrical battery recycling machine produced by Henan DOING adopts advanced mechanical crushing and physical separation technology to sort out copper, aluminum, iron, graphite powder, lithium cobalt oxide powder and diaphragm in waste lithium batteries, which can achieve a separation rate of more than 98%, and can achieve efficient recovery of valuable metals. Our lithium battery recycling equipment can not only recycle and process cylindrical batteries, but also process mobile phone lithium batteries, soft-pack lithium batteries, automotive lithium batteries, etc.

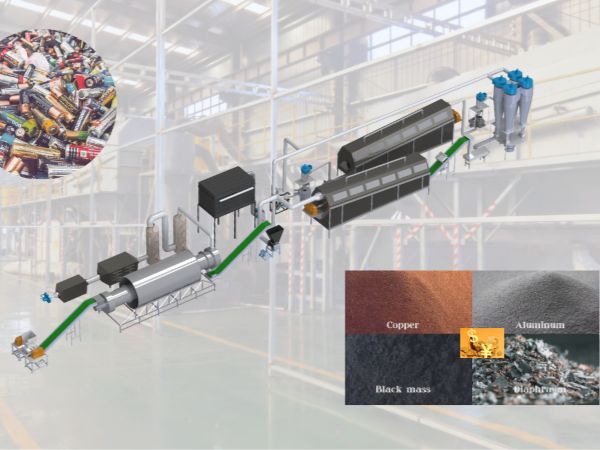

Cylindrical battery recycling machine 3D diagram

Cylindrical battery recycling machine 3D diagram

Waste cylindrical batteries usually contain 10%-15% copper, 10%-15% aluminum, 3%-5% iron and about 50% graphite powder and lithium cobalt oxide powder. These are precious resources and have high recycling value.

DOING cylindrical battery recycling machine adopts dry physical separation method, through the processes of shredding, crushing, magnetic separation, screening, gravity separation, etc. The electronic waste is turned into treasure through physical recycling methods, which not only realizes the recycling of waste lithium battery resources, but also brings good economic benefits.

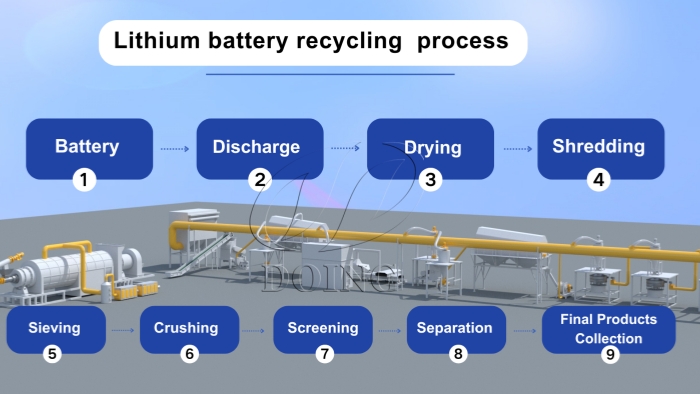

Cylindrical battery recycling process

Cylindrical battery recycling process

The specific process flow of cylindrical battery recycling machine is as follows:

1. The used cylindrical batteries are soaked in NaCl solution for 2-3 days to fully discharge and ensure the safety of the entire recycling process. The discharged used cylindrical batteries are dried naturally or in a drying furnace and then sent to the shredder to be shredded to about 3-5 cm.

2. After passing through the pulverizer, the battery raw materials are transported to the crusher for further crushing to less than 1 cm.

3. The crushed materials enter the first-stage drum screening machine to screen out 70%-80% of the black lumps.

4. Then the materials enter the linear screen, and the upper layer of the linear screen separates the copper-aluminum-iron mixture, and the lower layer separates some black powder. The pipe on the linear screen separates the plastic diaphragm. The magnetic separator behind the linear screen separates the iron.

5. The matter then enters the secondary crusher for further crushing. Then it enters the secondary drum screening machine to separate a small amount of black powder. Then the copper-aluminum mixture enters the mill for grinding.

6. Finally, it comes to the selection system, and the materials pass through the circular vibrating screen and enters the airflow separator to achieve the ideal multi-stage screening effect, and obtains copper, aluminum and a small amount of black powder.

DOING Cylindrical battery recycling machine

DOING Cylindrical battery recycling machine

The whole set of DOING cylindrical battery recycling machine is equipped with an environmentally friendly dust removal device to collect dust without any pollution, in line with environmental protection standards.

Henan DOING is a manufacturer specializing in the crushing and recycling of waste lithium batteries. It can also be customized according to customer needs to meet the production needs of different customers. At the same time, DOING supports on-site testing, after-sales installation and other services.If you are interested in the recycling business, please call for detailed consultation and come to the factory for an on-site visit!

News

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.