WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Mobile phone lithium battery recycling machine

We provide free trial service.

You can also visit our factory.

- Tel: +86 371 5677 1821

- WhatsApp: +86 150 3713 8562

- Phone: +86 150 3713 8562

- Email: market@doinggroup.com

The service life of mobile phone lithium batteries is about 3 years. If not handled properly, the heavy metals contained in the scrapped mobile phone lithium batteries will inevitably pollute the environment. In addition, cobalt, lithium, copper and diaphragm in waste lithium batteries have high recycling value. DOING has designed mobile phone lithium battery recycling machine, which uses a combination of crushing, screening and airflow seperation to separate and recycle metals and black mass from mobile phone waste lithium batteries.

Mobile phone lithium battery recycling machine

Mobile phone lithium battery recycling machine

Equipment information:

Capacity: 500kg/h-2000kg/h;

In order to ensure more efficient recycling of lithium batteries, DOING can customize waste lithium battery recycling machine for customers according to different types of raw materials.

Equipment working conditions: continuous work, 10h/day;

Production line operation personnel required: 2 people;

The specific occupancy area needs to be considered comprehensively based on factors such as equipment specifications, configuration, and site conditions. The size of DOING mobile lithium battery recycling machine usually starts from 154.0m*27.0m.

Applicable materials: lithium iron phosphate batteries, ternary lithium batteries, cobalt oxide batteries, lithium manganese oxide batteries, polymers, cylindrical lithium batteries, square lithium batteries, power batteries, mobile phone lithium batteries, battery positive and negative plates, etc.

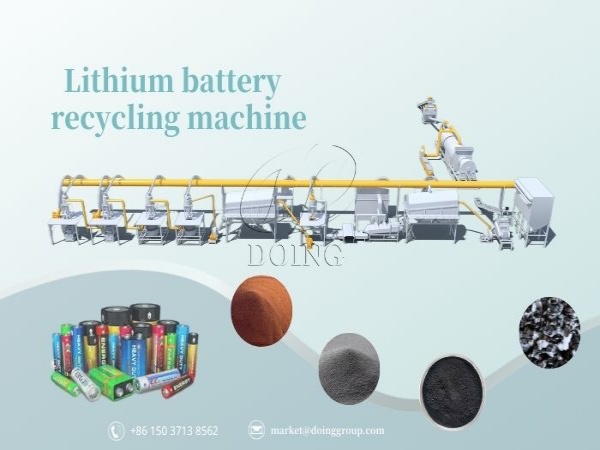

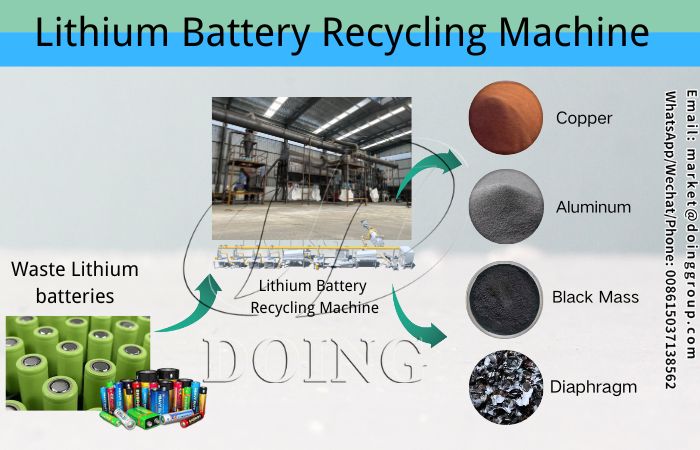

Final products: copper, aluminum, iron, black mass, plastic diaphragm.

Applicable materials

Applicable materials

Product introduction:

Mobile phone lithium battery recycling machine is mainly used for crushing, sorting and recycling of various lithium batteries such as mobile phone lithium batteries, power lithium batteries, soft-pack lithium batteries, hard-shell lithium batteries, etc., which can realize the classified recycling of copper, aluminum, iron, diaphragm, positive and negative electrode materials. The sorting purity of DOING lithium battery recycling machine can reach more than 98%, and the recovery rate can reach more than 99%.

Mobile phone lithium battery recycling machine

Mobile phone lithium battery recycling machine

Equipment configuration:

Mobile phone lithium battery recycling production line consists of crushing system, conveying system, screening system, separation system, PLC automatic control system, etc. DOING mobile phone lithium battery recycling machine is equipped with environmental protection dust removal system, and there is no waste gas and dust in the production process. Environmental protection meets the standards.

Process flow:

1. The waste lithium battery is first discharged by NaCl solution, and then sent to the shredder to be processed into small pieces.

2. The material is transported to the crusher for further crushing.

3. The crushed material enters the first-level drum screening machine to screen out 70%-80% of the black mass.

4. The material enters the linear screen, and the upper layer of the linear screen separates the copper-aluminum-iron mixture, and the lower layer separates some black powder. The pipe on the linear screen separates the plastic diaphragm. The magnetic separator behind the linear screen separates the iron.

5. The material enters the secondary crusher to continue to crush. Then it enters the secondary drum screening machine to separate a small amount of black powder. Then the copper-aluminum mixture enters the mill for grinding.

6. The material enters the final fine separation system to separate the remaining copper, aluminum and black powder.

The entire set of DOING mobile phone lithium battery recycling equipment is equipped with a cyclone dust collector to collect dust. No dust overflow, environmental protection standards meet.

Lithium battery recycling equipment

Lithium battery recycling equipment

Advantages of DOING mobile phone lithium battery recycling machine:

1. Multi-stage crushing + multi-stage sorting, the recovery rate can reach 99%, and the sorting purity can reach 98%;

2. Dry physical method, equipped with dust removal device throughout the process, no dust overflow, environmental protection standard;

3. Lithium battery recycling machine can meet the conventional recycling and processing of various lithium batteries, positive and negative electrode materials;

4. Factory assembly line process, PLC automatic control, saving labor costs.

Lithium battery recycling equipment

Lithium battery recycling equipment

As a lithium battery recycling equipment manufacturer with more than ten years of experience, Henan DOING can provide you with a suitable mobile phone lithium battery recycling machine according to your needs. Welcome to leave a message below to contact us.

News

DOING 100-150kg/h PCB Recycling Machine Shipped to Zambia, Powering Local E-Waste Automation

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Process Workflow and Equipment for Lithium Battery Recycling

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.