WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Plastic and aluminum separator machine

We provide free trial service.

You can also visit our factory.

- Tel: +86 371 5677 1821

- WhatsApp: +86 150 3713 8562

- Phone: +86 150 3713 8562

- Email: market@doinggroup.com

DOING Company plastic and aluminum separator machine is a production line that adapts mechanical crushing and separating technology, which can help you separate plastic and pure aluminum powder from waste aluminum plastic composite materials. Due to its high purity, the separated plastic and aluminum can be sold directly on the market at a good profit.

Materials that can be processed plastic and aluminum separator machine

Plastic and aluminum separator machine is suitable for processing a variety of aluminum-plastic composite materials, such as waste plastic aluminum foil, waste aluminum-plastic panels, toothpaste tubes, medical blister, pharmaceutical capsule boards, various aluminum plates, etc.

Plastic and aluminum separator machine

Plastic and aluminum separator machine

Different types of aluminum plastic composite materials have different aluminum contents. Generally speaking, if the aluminum content is higher, the separation effect will be better and the profit will be more considerable.

Processing flow of plastic and aluminum separator machine

The process of plastic and aluminum separator machine include crushing, grinding, circulation water cooling system, eddy-vibrating screen, electrostatic separation and pulse dust collector.

Combined with the video and text description below, you can more easily understand the processing flow of plastic and aluminum separator machine.

Crushing:

Crusher is used to crush materials into smaller pieces. Then the crushed materials are conveyed to the next step through wind transport conveyor. Moreover, when the air transport system is used to load materials under negative pressure, there will be no material jamming.

Grinding:

In order to separate aluminum and plastic more thoroughly, it is necessary to grind the mixed granules into plastic and aluminum mixture powder for further process.

Grinder

Grinder

Circulation water cooling system:

The crushing and grinding parts are equipped with a circulating water cooling system and are cooled by a circulating water cooling machine. The plastic will not melt or change color due to excessive temperature after long-term operation of the equipment.

Eddy-vibrating screen:

The eddy-vibrating screen is mainly used to control the particle size of ground materials. Only materials of suitable size can be sorted. Oversized materials are sent back to the grinder for further grinding.

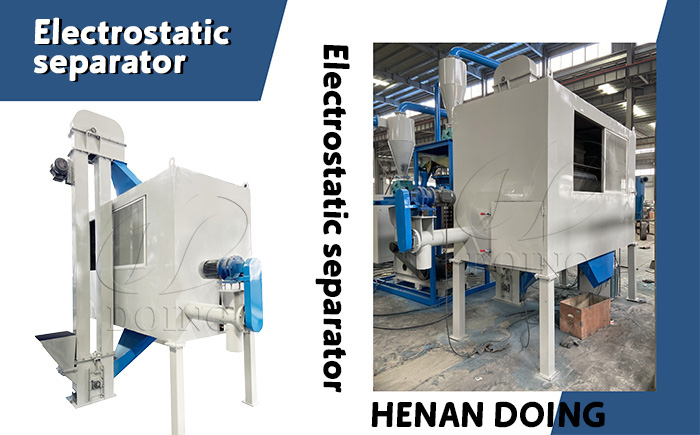

Electrostatic separator:

Materials of proper sizes enter the electrostatic separator through the bucket elevator. The electrostatic separator uses the different electrification properties of metals and non-metals to separate aluminum and plastics. After sorting, the purity of aluminum and plastic is as high as 99.9%, and the separated plastic and aluminum could be directly recycled to be sold in the market or made into new products.

Electrostatic separator

Electrostatic separator

Dust removal system:

During the whole process, we have an automatic dust removal system for dust removal.

Compared to low value waste aluminum plastic composite materials, the recycled pure plastic and aluminum would bring high benefit. Here is a profit analysis of a plastic and aluminum separator machine with a processing capacity of 200-300kg/h, which you can refer to.

Profit analysis

Profit analysis

Advantages of plastic and aluminum separator machine

Advantages of plastic and aluminum separator machine

Advantages of plastic and aluminum separator machine

1.Dry separation process; no liquids or chemicals required; low expenditure of energy;

2.The highest purity of aluminum plastic sorting purity can reach more than 99.9%.

3.PCL control system, high automation program, simple operation and stable performance, minimum use of staff, low level of personnel deployment;

4.No waste water exhaust. Real green environmental sorting, no secondary pollution.

We are experts in the field of solid waste recycling especially metal recycling. If you have any question about plastic and aluminum separator machine, feel free to contact us.

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.