WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Is the DOING lithium baterry recycling machine environmentally friendly?

March 18, 2025

March 18, 2025- Industry News

- Leave a message

- Chat online

Traditional chemical lithium battery recycling methods have environmental risks.DOING's advanced physical lithium baterry battery recycling technology provides an environmentally friendly and cost-effective solution. Next, we will introduce to you how DOING lithium baterry recycling machine reduces environmental impact, meets international environmental protection requirements, and brings economic benefits to enterprises.

Raw materails of lithium baterry recycling machine

Raw materails of lithium baterry recycling machine

1. Eliminate misunderstandings about physical lithium baterry battery recycling equipment

Physical recycling, also known as mechanical recycling, extracts battery materials through physical methods such as crushing and sorting. Some people have expressed concerns about its environmental friendliness, mainly focusing on the following two aspects:

Dust and exhaust gas leakage: Old crushing equipment lacks an effective filtration system, which may lead to the leakage of heavy metal dust and harmful gases.

Treatment of sorting residues: Incompletely separated electrolyte or metal debris may contaminate the soil.

However, these problems are not inherent defects in the technology of physical lithium baterry battery recycling equipment, but are caused by backward equipment and irregular operation.

2. DOING's environmentally friendly lithium baterry battery recycling technology breakthrough

DOING's advanced physical lithium battery recycling equipment has minimized environmental impact through three major innovations and met international environmental standards:

a. Closed-loop design to prevent pollution leakage:

Pulse dust removal system of DOING lithium baterry recycling machine

Pulse dust removal system of DOING lithium baterry recycling machine

Dust control: Nitrogen is used to protect the crushing chamber and pulse dust removal system to control the dust concentration in the working environment to meet the environmental protection standards of most countries and EU standards, eliminating the risk of combustion and explosion during the crushing process.

b.Environmentally friendly material sorting technology:

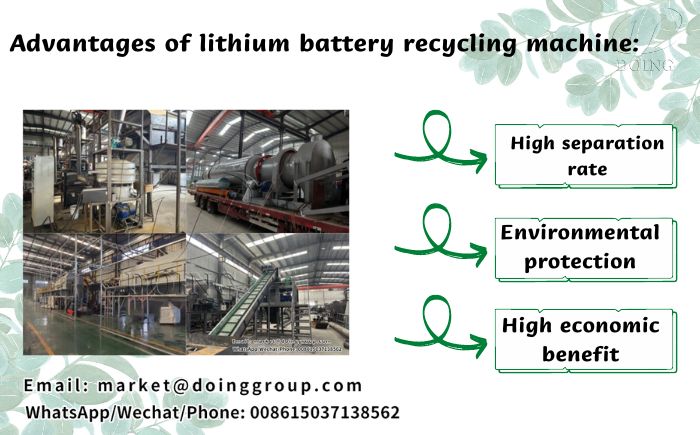

DOING environmentally friendly lithium baterry recycling machine

DOING environmentally friendly lithium baterry recycling machine

Dry sorting technology: Using magnetic separation and eddy current sorting technology to extract copper, aluminum and black powder, the whole process does not require chemical solvents to avoid the generation of wastewater.

c. Waste recycling:

Plastic diaphragms: Sorted plastic diaphragms can be made into recycled particles for the manufacture of automotive dashboards and other parts.

d.Residues:

Unrecyclable residues are solidified by high-temperature sintering of heavy metals, and are made into roadbed materials that have been used in high-speed rail projects.

3.Physical V.S. chemical lithium battery recycling technology

Recycling method Carbon emissions per ton of battery processing (kg CO₂)Water consumption (tons)

| Recycling method | Carbon emissions per ton of battery processing (kg CO₂) | Water consumption (tons) |

| Physical recycling | 320 | 0.5 |

| Hydrometallurgy | 1150 | 8.2 |

| Pyrometallurgy | 2400 | 1.2 |

Based on network data feedback and our experiments, we have compiled the above content for your reference.DOING's physical lithium baterry battery recycling technology has carbon emissions of only 28% of hydrometallurgy, and does not produce acidic wastewater, which is more in line with strict environmental regulations such as the EU's "New Battery Regulations".

4. Global Customer Cases of DOING lithium baterry recycling machine

Case 1: European Battery Manufacturer

After a European battery manufacturer introduced DOING's physical lithium baterry battery recycling line, it reduced CO₂ emissions by 12,000 tons per year, equivalent to planting 220,000 trees; the recycled cobalt and nickel purity reached 99.5%, which was directly used in new battery production, reducing raw material costs by 35%, and reusing environmental resources.

DOING lithium baterry recycling machine Installation case

DOING lithium baterry recycling machine Installation case

Case 2: Malaysian Recycler

A Malaysian recycling company used DOING's lithium baterry battery sorting and recycling equipment to process battery black powder to international standards and obtain additional income through carbon credit trading.

DOING environmentally friendly lithium baterry recycling machine manufacturer

DOING environmentally friendly lithium baterry recycling machine manufacturer

The above is the full introduction of DOING lithium baterry recycling machine, which not only solves the environmental problems of traditional lithium baterry battery recycling technology, but also brings significant benefits to the company. If you have lithium baterry battery raw materials and processing volume that need to be processed, you can send them to us. Our sales team provides one-stop services from raw material evaluation to equipment purchase, plant site selection, machine installation, and training and operation, and fully helps you to start a lithium baterry battery recycling business.

Contact Us

- Email:

- Tel/WhatsApp:

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.