WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Is there a solution to e-waste recycling with high profit?

September 12, 2023

September 12, 2023- FAQ

- Leave a message

- Chat online

E-waste is rich in valuable materials, which have high market value. The profit generated from recycling e-waste is affected by multiple factors. However, the efficiency of the recycling process is crucial to profits generated. If the recycling process is inefficient, it will waste a lot of time and resources, and it will also affect the company's profits. Therefore, it is recommended to adopt more efficient recycling equipment and technology to recycle e-waste in order to obtain high profits.

E-waste

E-waste

With over 13 years of experience in waste recycling machine manufacturing, DOING designed automatic e-waste recycling equipment, including e-waste pcb recycling machine, copper cable wire recycling granulator and radiator crushing separation machine according to different characteristics of the types of e-waste, which can help you get pure metal with high efficiency. Next I will introduce it one by one in details.

1.E-waste pcb recycling machine

DOING E waste pcb recycling machine is specially designed to get metals and resin fiber by processing waste circuit boards. Compare with other machine, this e-waste recycling machine can handle a wider range of circuit boards, such as, copper clad laminates, computer motherboards, TV boards, printed circuit boards, various waste electrical motherboards, etc. Besides, our e-waste recycling machine is equipped with PLC control system, easy to operation, only need one or two workers.

E waste pcb recycling machine

E waste pcb recycling machine

Separation rate is the most important point in distinguishing whether a machine is efficient or not. Sufficient crushing makes the sorting more efficient and the metals more pure. Our e-waste pcb recycling machine has hammerhead crusher, hammer crusher and double-shaft shredder, which can crushing waste boards into powders. With the air and electronic separators, the separation rate can reach 99%. Almost all of the metals in e-waste can be separated, which can maximize the profit.

The final products of E waste pcb recycling machine has many usages, so the profit is very considerable. Here is a profit analysis chart that we made for your reference.

Profit analysis of e-waste pcb recycling machine

Profit analysis of e-waste pcb recycling machine

2.Copper cable wire recycling granulator

Copper cable wire recycling granulator adapts advanced technology and materials to process various of wires and cables for pure copper and plastic with high quality without affecting their recycling value. Besides, the copper cable wire machine is equipped with high-precision separation equipment such as air separator, electrostatic separator and linear vibrating screen, which can effectively separate copper and plastic without causing pollution to the environment.

Copper cable wire recycling granulator

Copper cable wire recycling granulator

The copper cable wire recycling granulator has different processing capacities from 200kg/h to 1t/h. It can process a large amount of waste wires and cables in a short time, improve production efficiency, and meet the needs of industrial production. Adopt PLC control system to reduce the cost and labor of manual operation.

The profit analysis of copper wire and cable recycling granulator for recycling waste wires and cables is as follows.

Profit analysis of copper cable wire recycling granulator

Profit analysis of copper cable wire recycling granulator

It is worth noting that the copper content of different types of waste wires and cables varies greatly. For example, the copper content of square wires is about 62-75%, and the copper content of household appliance plug wires is generally about 25%. When you purchase waste wire and cable, copper content and price need to be considered.

3.Radiator crushing separation machine

If you have large amount of waste radiators or deformed radiators, a radiator crushing separation machine will be a better choice. Radiator crushing separation machine is professional equipment to recycle the radiator for air conditioners and car water tanks and refrigerator and separate aluminum and copper out. It has high separation rate and automation, very suitable for large scale waste radiator recycling to use.

Radiator crushing separation machine

Radiator crushing separation machine

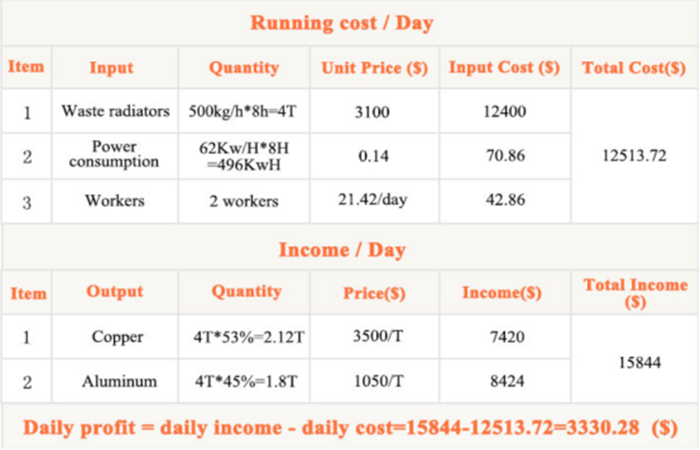

The table below is an analysis of the profitability of this radiator crushing separation machine, but there are differences in the prices of copper and aluminium in different cities, so this table is for reference only.

Profit analysis of radiator crushing separation machine

Profit analysis of radiator crushing separation machine

The above profit analysis is calculated based on the processing capacity of 500kg/h. Due to the difference of costs of e-waste raw materials, labor, power consumption, and the selling price of final products obtained from e-waste, etc., you can calculate it according to your actual situation.

If you want to start e-waste recycling business and know more information about the machine. You can contact us and we will give you our best support.

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.