WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How do you set up a battery scrap recycling plant?

February 18, 2025

February 18, 2025- FAQ

- Leave a message

- Chat online

As the demand for sustainable energy solutions grows, battery scrap recycling has become an essential part of the circular economy. Setting up a battery scrap recycling plant is a strategic move for businesses looking to contribute to environmental sustainability while tapping into a lucrative market. If you're considering entering this industry, here's a step-by-step guide to help you build a successful battery scrap recycling plant.

1. Understand the Battery Recycling Process

There are many types of batteries, especially lithium-ion batteries used in electric vehicles, smartphones and laptops, which are currently the most widely recycled batteries due to their abundant raw materials, low cost, high recycling value and relatively simple recycling process.

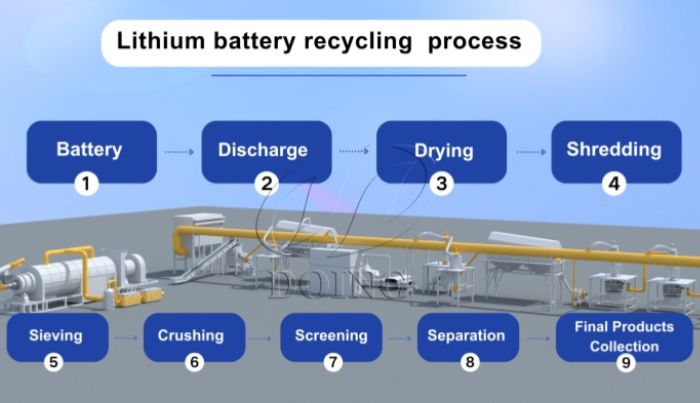

Lithium battery recycling process

Lithium battery recycling process

Before setting up a battery scrap recycling plant, it is crucial to understand the recycling process. The recycling of lithium batteries usually goes through several stages, including collection, sorting, discharge, disassembly and material recovery. Each step requires specialized equipment and expertise to ensure efficiency and safety.

2. Conduct Market Research

Analyze the market demand for recycled battery materials in your region. Identify the types of lithium batteries most commonly used, such as lithium cobalt oxide batteries LCO, lithium nickel manganese cobalt oxide batteries NMC, lithium iron phosphate batteries LFP, etc., and adjust your plant’s operations accordingly. Understanding your target market will help you design a plant that meets specific needs.

3. Choose the Right Location

Selecting an appropriate location for your battery scrap recycling plant is critical. Consider factors such as proximity to battery collection centers, transportation infrastructure, and local regulations. A well-chosen location can reduce operational costs and streamline logistics.

4. Invest in Quality Recycling Equipment

The success of your battery scrap recycling plant depends heavily on the equipment you use. Invest in reliable and efficient machinery designed for battery recycling, such as shredders, crushers, and separators. High-quality equipment ensures better material recovery rates and minimizes environmental impact.

Henan DOING battery recycling equipment

Henan DOING battery recycling equipment

Henan DOING battery recycling equipment can be used to recycle and process various types of lithium-ion batteries, such as car lithium batteries, mobile phone lithium batteries, and soft lithium batteries, etc. This machine adopts advanced crushing and separation system to sort out copper, aluminum, iron, graphite powder, and diaphragm in waste lithium batteries, which can achieve a separation rate of more than 98%, and can achieve efficient recovery of valuable metals.

At Henan DOING, we specialize in providing high-quality lithium battery recycling equipment designed to maximize efficiency and minimize environmental impact. Our solutions are tailored to meet the unique needs of battery scrap recycling plants.

5. Obtain Necessary Permits and Certifications

Compliance with local and international regulations is essential for operating a battery scrap recycling plant. Obtain the required permits, licenses, and certifications to ensure your plant meets environmental and safety standards. This step not only legitimizes your operations but also builds trust with clients and stakeholders.

Battery scrap recycling plant

Battery scrap recycling plant

6. Develop a Waste Management Plan

Battery recycling generates by-products and waste materials that need proper disposal. Develop a comprehensive waste management plan to handle hazardous and non-hazardous waste responsibly. This plan should align with environmental regulations and demonstrate your commitment to sustainability.

7. Train Your Workforce

A skilled workforce is essential to the smooth operation of a battery scrap recycling plant. Providing your employees with professional training on safety protocols, equipment operation, and recycling processes can significantly improve efficiency and reduce the risk of accidents. Well-trained employees not only ensure the correct use of equipment, but also optimize the recycling process, thereby improving overall operational efficiency.

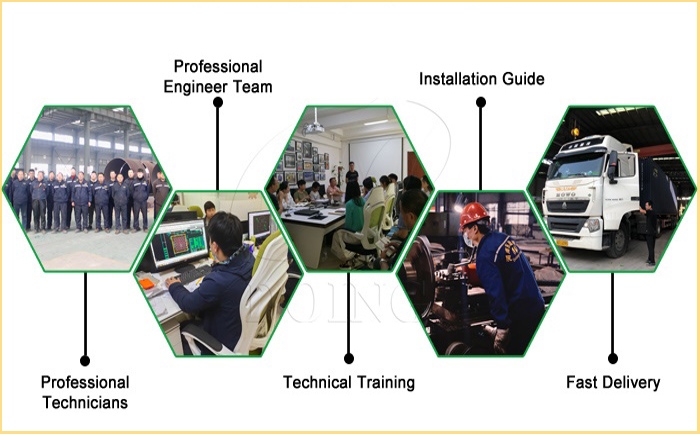

Professional equipment services in Henan DOING

Professional equipment services in Henan DOING

If you need support with plant layout, equipment installation, or worker training, Henan DOING Company can provide a full range of services, including customized plant design, equipment installation guidance, and worker operation training to help your plant achieve efficient and safe operation.

8. Establish Partnerships

Collaborate with battery manufacturers, waste collection agencies, and material buyers to create a sustainable supply chain. Strong partnerships can ensure a steady flow of raw materials and a reliable market for recycled products.

By following these steps and partnering with the right equipment provider, you can set up a successful battery scrap recycling plant that meets industry standards and contributes to a greener planet. Reach out to us now to get started!

Contact Us

- Email:

- Tel/WhatsApp:

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.