WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

What technologies are used in lithium-ion battery recycling?

February 7, 2025

February 7, 2025- Industry News

- Leave a message

- Chat online

The global lithium battery recycling market is expected to grow from US$16.2 billion in 2024 to US$56.9 billion in 2032, with a compound annual growth rate of 17%. People are paying more and more attention to lithium-ion battery recycling technology. The following are the most cutting-edge lithium-ion battery recycling technologies and their breakthrough applications, providing sustainable solutions for companies and investors.

Waste lithium-ion batteries for recycling

Waste lithium-ion batteries for recycling

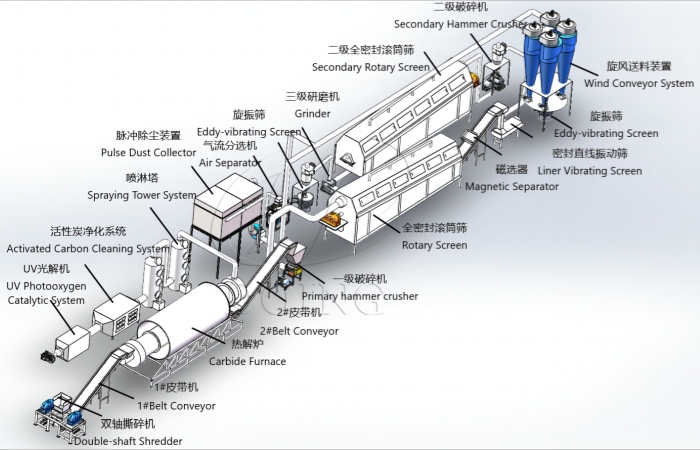

1. Physical and mechanical sorting technology: efficient separation of core materials

The dry physical sorting process is used to first crush the lithium-ion battery into small pieces through crushing, drying, density sorting and other steps, which will crush the shell and expose the internal components, such as electrodes, diaphragms and electrolytes. After crushing, screening technology is used. Particles of different sizes are separated according to physical size. For example, larger metal shell fragments can be separated from finer powdered materials containing active lithium-ion battery materials, so as to accurately extract copper, aluminum, and black powder (containing lithium, cobalt, nickel, etc.) from lithium-ion batteries.

3D diagram of Henan DOING lithiu-ion battery recycling equipment

3D diagram of Henan DOING lithiu-ion battery recycling equipment

High recovery rate: The recovery rate of metal materials can reach more than 98%, and the purity of black powder meets the needs of direct reuse in the production of new lithium-ion batteries.

Safety and environmental protection: Dry processing throughout the process to avoid electrolyte leakage and secondary pollution.

Henan DOING's customers' lithium-ion battery recycling equipment has been applied on a large scale, with an annual processing capacity of tens of thousands of tons, and cooperates with many international lithium-ion battery manufacturers.

Henan DOING lithium-ion baterry recycling equipment

Henan DOING lithium-ion baterry recycling equipment

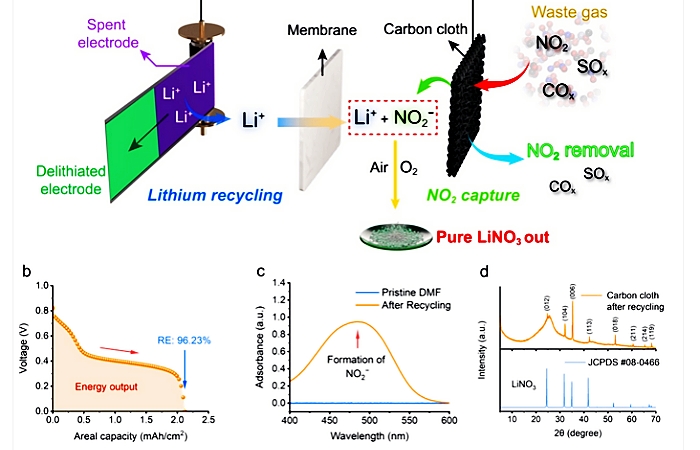

2. Electrochemical recycling technology:

This technology uses the potential difference between the positive electrode material of waste lithium-ion batteries and nitrogen dioxide (NO₂) in industrial exhaust gas to spontaneously drive lithium ions to escape and generate high-value lithium nitrate salts, while outputting a voltage of about 0.4V to achieve energy recovery. The advantage is that no external energy input is required, reducing operating costs; the lithium recovery rate is as high as 99%, and the pollutant NO₂ is converted into lithium nitrate to reduce carbon emissions. However, the equipment cost required for this technology is high and the technology maturity is insufficient, which may affect its effect in practical applications.

Electrochemical recycling technology

Electrochemical recycling technology

3. Hydrometallurgical technology:

Hydrometallurgy extracts metals such as lithium, cobalt, and nickel from lithium-ion battery black powder through acid leaching, solvent extraction and other steps, it can recover key metals and convert them into lithium-ion battery-grade raw materials. Suitable for recycling lithium-ion batteries with complex chemical systems (such as NMC, LFP, etc.) and refined recycling of high-value-added metals (such as cobalt), but this technology faces challenges such as wastewater treatment, cumbersome procedures and high costs.

4. Pyrometallurgical technology:

This technology uses high-temperature smelting technology to convert lithium-ion battery materials into alloys and then separate the metal components. This technology has a large processing capacity and strong compatibility, and is suitable for mixed lithium-ion battery waste, but it has high energy consumption and there are problems such as raw material loss, waste gas and dust emissions.

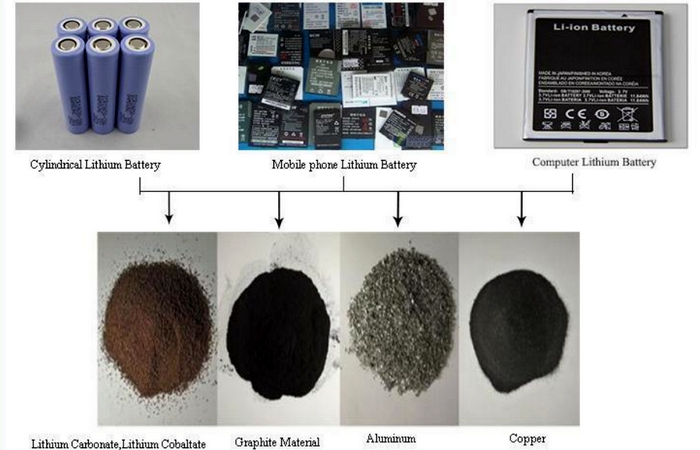

The products of lithium-ion recycling technology

The products of lithium-ion recycling technology

The above is an introduction to lithium-ion battery recycling technology. If you want to adopt environmentally friendly and efficient lithium-ion recycling technology, Henan DOING can provide you with high-quality lithium-ion recycling equipment, comprehensive installation solutions, and professional technical guidance.

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.