WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Waste lithium battery processing equipment

We provide free trial service.

You can also visit our factory.

- Tel: +86 371 5677 1821

- WhatsApp: +86 150 3713 8562

- Phone: +86 150 3713 8562

- Email: market@doinggroup.com

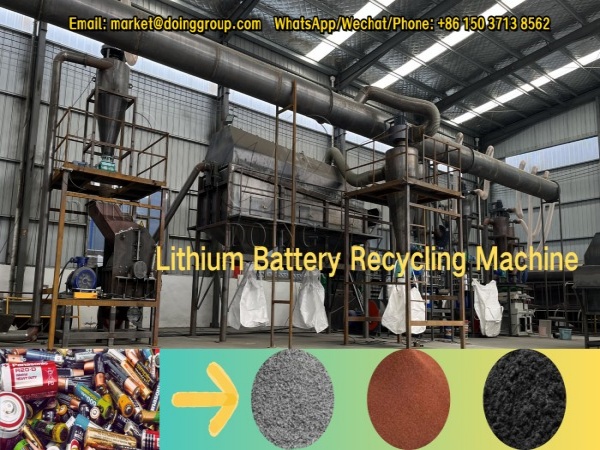

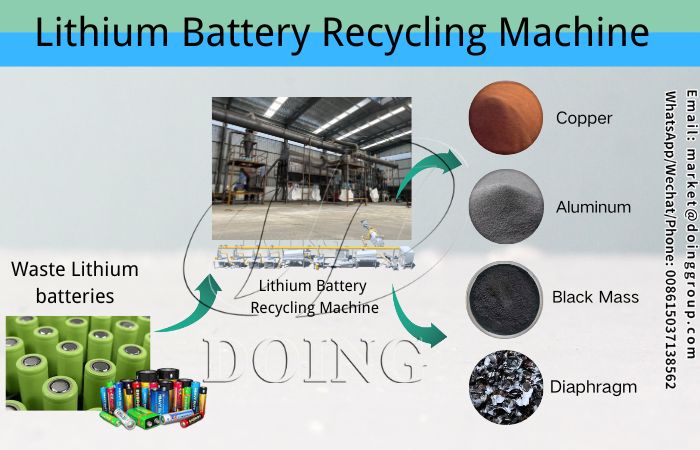

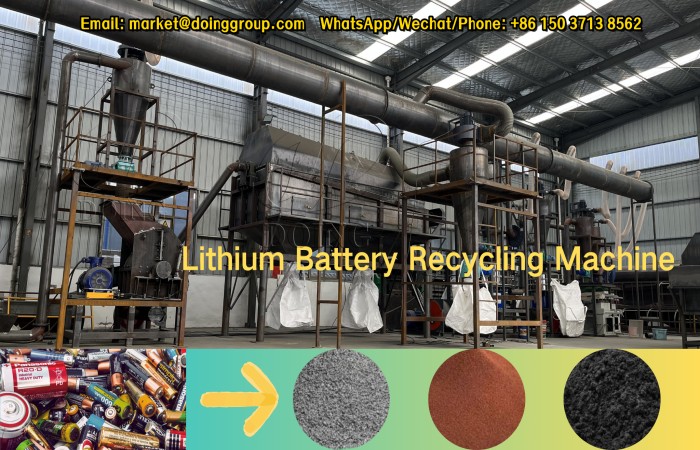

Waste lithium battery processing equipment can effectively process various waste batteries, separate copper, aluminum, graphite powder and lithium cobalt oxide powder, and achieve efficient recovery of valuable metals. Waste lithium battery recycling and processing equipment mainly adopts physical processes to sort out the positive and negative electrode materials in waste lithium batteries through crushing, separation and other steps.

Waste lithium battery processing equipment

Waste lithium battery processing equipment

Characteristics and advantages of waste lithium battery processing equipment:

1. Waste lithium battery processing equipment has a wide range of uses and can process lithium batteries of various types and different materials, including soft packs, hard shells, steel shells, cylindrical lithium batteries, etc.

2. Waste lithium battery processing equipment has high efficiency, long and stable service life.

3. The production line of waste lithium battery processing equipment is environmentally friendly. The complete set of waste lithium battery processing equipment production line can recycle copper, aluminum, black powder, diaphragm and other products, with a recovery rate of up to 98%.

Waste lithium battery processing equipment

Waste lithium battery processing equipment

Raw materials that can be processed by waste lithium battery processing equipment

Waste lithium battery recycling and processing equipment is suitable for the recycling and processing of waste lithium batteries such as ternary lithium batteries, lithium iron phosphate batteries, lithium cobalt oxide batteries, lithium manganese oxide batteries, mobile phone lithium batteries, new energy vehicle power batteries, electric vehicle lithium batteries, 18650 lithium batteries, lithium battery positive and negative plates, or lithium batteries with different shell materials, such as soft-pack batteries, hard-shell batteries, square batteries, cylindrical batteries and other waste batteries.

Raw materials

Raw materials

Process flow of waste lithium battery processing equipment

The waste lithium battery processing equipment produced by DOING Company adopts a new type of mechanical crushing and sorting technology, including discharge, crushing, screening, magnetic separation, separation and other links. Its process flow is as follows:

Discharge: The waste lithium battery is soaked in salt water to ensure that the subsequent crushing is not charged and prevents it from burning and exploding.

Shred + crushing: The discharged lithium battery is sent to the shredder to be torn into small pieces, and then coarsely broken by the crusher, broken into about 1 cm, the shell, positive and negative electrodes are separated, and enter the screening section.

Screening: Drum screening, screening out black powder. Some manufacturers on the market use linear screens in this section, with small output and unclean screening. The drum screen configured by Doing Company can achieve a screening rate of 70%-80%.

Note: If the customer needs to collect the diaphragm between the positive and negative electrodes of the battery, Doing Company can configure a linear screen for screening. If the diaphragm does not need to be collected, a carbonization furnace can be configured for carbonization to remove the diaphragm.

Waste lithium battery processing equipment

Waste lithium battery processing equipment

Sorting: The crushed lithium battery material enters the magnetic separator, and the iron is screened out by magnetic force; the remaining materials are crushed and ground into screening equipment, such as rotary vibrating screen, specific gravity separator, eddy current separator, and the size difference and weight difference between particles are used to effectively separate copper, aluminum and black powder.

After the above process, the metal and black powder in the waste lithium battery can be effectively recovered. The separated materials can be reused, which not only reduces environmental pollution, but also reduces the production cost of new batteries, forming sustainable development.

Products and uses of waste lithium battery processing

DOING lithium-ion battery recycling machine adopts dry mechanical crushing and physical sorting technology, which can efficiently recycle valuable parts of lithium-ion batteries, such as black powder, diaphragm, copper and aluminum. The separated copper and aluminum can be sold directly to the metal trading market for profit. The black substances are mainly graphite powder and lithium cobalt oxide, both of which have a wide range of uses. Taking graphite powder as an example, graphite powder can be used in environmental protection and energy saving, industrial product manufacturing and other aspects, and its utilization value is very high.

DOING waste lithium battery processing equipment

DOING waste lithium battery processing equipment

As a professional manufacturer of waste lithium battery processing equipment, DOING is committed to providing customers with feasible solutions and professional support, including equipment installation and commissioning, technical training, after-sales service, etc. We provide 500-3000kg/h lithium battery processing equipment and also support additional customized services. If you want to know more about DOING waste lithium battery processing equipment, please contact us immediately.

News

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.