WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

3D video introduction of aluminum plastic recycling equipment

September 14, 2023

September 14, 2023- Video

- Leave a message

- Chat online

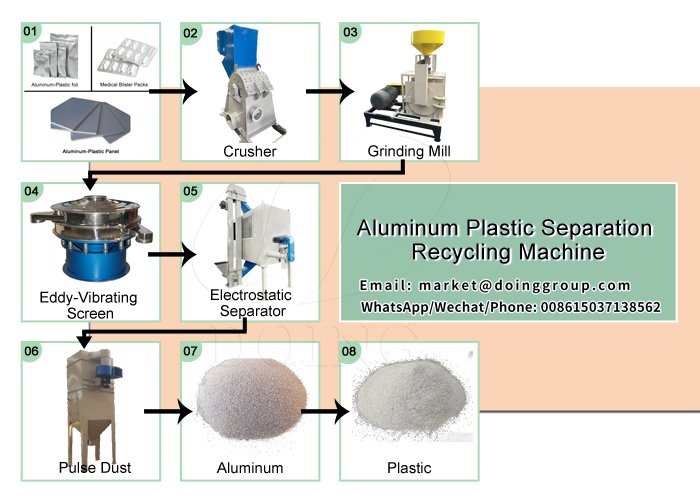

This 3D video is designed by our excellent engineers, which shows the whole running process of DOING aluminum plastic recycling equipment. If you want to recycle waste medical blister, aluminum-plastic foil or aluminum-plastic panels to get separated aluminum and plastic, you can watch this video to know more about it.

The raw material processed in this video is waste medical blister. The 3D video shows a configuration of an aluminum plastic recycling equipment with a processing capacity of 300kg/h, which mainly includes a feeding conveyor belt, crusher, grinder, electromagnetic feeder, eddy-vibrating screen, electrostatic separator and dust removal system.

Aluminum plastic recycling equipment

Aluminum plastic recycling equipment

We have different processing capacity and configurations of aluminum plastic recycling equipment for choosing considering of different requirements of customers. There will be differences in configuration and capacity, but the basic principles are the same.

Aluminum plastic recycling equipment

Aluminum plastic recycling equipment

The detailed process is as follows:

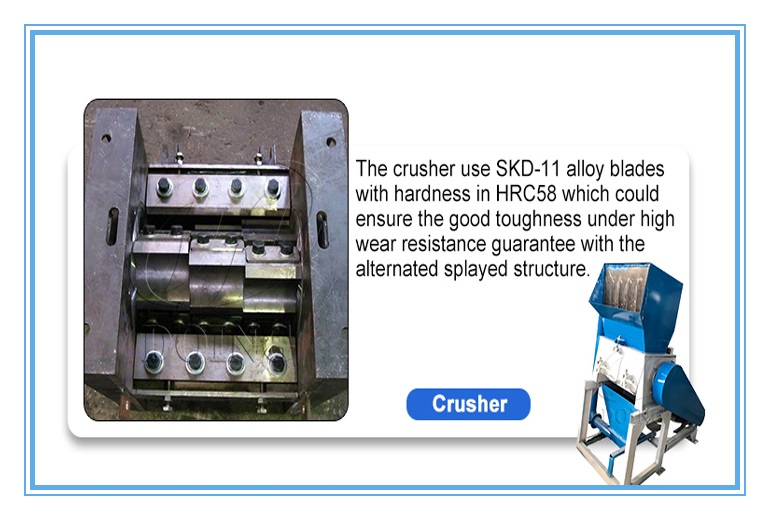

1. Crushing

The first step is crushing. The crushed materials are conveyed to the next step through wind transport conveyor.

Crusher

Crusher

The wind transport conveyor can prevent the pollution of the factory working environment caused by flying materials and keep the environment around the machine clean. Moreover, when the air transport system is used to load materials under negative pressure, there will be no material blocked.

2. Grinding

The crushed materials enter the electromagnetic feeder, which can control the feeding speed so that the materials enter the grinder evenly.

3. Circulation water cooling system

The grinder is equipped with a circulating water cooling system, which can reduce the plastic melting caused by the high temperature generated during the grinding process.

4. Eddy-vibrating screen

The eddy-vibrating screen is mainly used to control the particle size of ground materials.

5. Electrostatic separator

The electrostatic separator uses the different electrification properties of metals and non-metals to separate aluminum and plastics. After sorting, the purity of aluminum and plastic is as high as 99.9%, and it can even be sold directly.

Electrostatic separator

Electrostatic separator

6. Dust removal system

During the whole process, we have an automatic dust removal system for dust removal.

The aluminum plastic recycling equipment is controlled by PLC control system, and just one or two worker for the entire operation. Because of the high purity and quality of the separated aluminum and saving labor and energy consumption, DOING aluminum plastic recycling equipment can bring you more profits. Here is a profit analysis chart that we made for your reference.

Profit analysis

Profit analysis

Due to the differences in the costs of raw materials, labor, electricity consumption, and the selling price of aluminum powers, the actual profit will fluctuate.

Henan Doing Company is specialized in waste recycling machine more than twelve years, and we have own high qualified engineer team. If you want to know more information about aluminum plastic recycling equipment, please contact us, and we will give you our best support.

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.