WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How is charcoal made?

November 28, 2024

November 28, 2024- FAQ

- Leave a message

- Chat online

Charcoal is made by heating biomass waste such as wood and fruit shells in an oxygen-deficient or low-oxygen environment. This process is called carbonization. The carbonization process removes moisture, volatile substances and other impurities from the wood, leaving behind a substance that is almost pure carbon, namely charcoal.

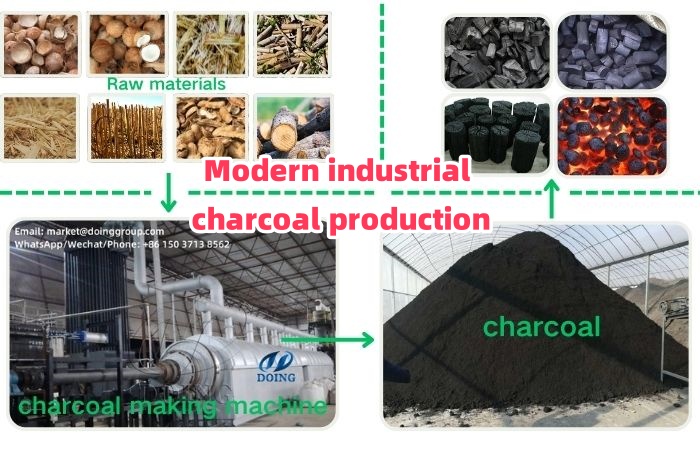

There are many materials available for making charcoal, which can be mainly divided into the following categories:

1. Various biomass: such as rice husks, sawdust, coconut shells, olive shells, palm shells, corn cobs, straw, bamboo, wood chips, wood, etc.;

2. Sludge: urban sludge, municipal sludge, industrial sludge, etc.;

3. Garbage: urban domestic waste, electronic waste, solid waste, etc.;

Materials available for making charcoal

Materials available for making charcoal

So how should charcoal be made? After understanding, the existing methods of making charcoal mainly include the following two:

1. Kiln burning method

The kiln burning method is a traditional method of making charcoal. It is made by building a kiln with mud, filling it with firewood, controlling the temperature and oxygen concentration, and making charcoal by not fully burning the wood in the kiln. However, this method is extremely inefficient in producing charcoal, and it is easy to produce smoke pollution, and the environmental protection is not up to standard.

Kiln burning method

Kiln burning method

2. Modern industrial method - biomass pyrolysis carbonization furnace

The modern industrial method of making charcoal requires the use of professional charcoal manufacturing equipment - biomass pyrolysis carbonization furnace. The pyrolysis carbonization furnace controls the temperature, oxygen content and other conditions to make biomass waste undergo pyrolysis reaction in a high temperature and oxygen-deficient environment to produce combustible gas and charcoal. The charcoal produced by this method is of high quality and good quality, and the equipment can operate continuously with extremely high production efficiency.

Modern industrial method

Modern industrial method

Based on the above analysis, we can know that modern mechanism charcoal is the best method. In fact, biomass pyrolysis carbonization furnaces are continuous and intermittent. If you want to know the specific differences between them, please refer to this article: [What is the difference between intermittent carbonization furnace and continuous carbonization furnace? ]

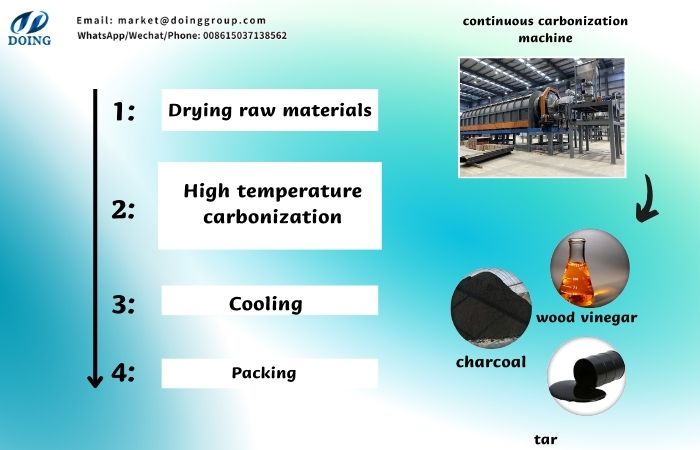

How does the biomass pyrolysis carbonization furnace work?

1. Raw material preparation: Determine whether it needs to be crushed and dried according to the particle size and moisture content of the biomass raw material. It is recommended that the moisture content of the raw material is less than 15% and the particle size is within 30mm. If drying is required, the raw materials need to be sent to the drum dryer and then to the carbonization furnace for high-temperature carbonization.

2. Carbonization process: The biomass is heated to a certain temperature (400℃~600℃) in the furnace. In an oxygen-deficient or micro-oxygen environment, the volatile components in the raw materials are driven out through pyrolysis reaction to form charcoal. The combustible gas generated in this process is transferred between the flue gas circulation system and recycled.

3. Cooling process: The charcoal is discharged from the charcoal outlet. After cooling, it can be collected and packaged.

Working process of carbonization machine

Working process of carbonization machine

Features of machine-made charcoal

Charcoal made from biomass pyrolysis carbonization furnace has many advantages:

1. Low water content: The water content of machine-made charcoal is usually within 5%, which is much lower than ordinary charcoal. This makes machine-made charcoal easier to ignite and burn.

2. Non-toxic and odorless: After carbonization, the odor and harmful substances in the wood are removed from the machine-made charcoal, and it will not produce pungent smoke or chemical odor when burned, which is environmentally friendly and healthy.

3. High energy: The fixed carbon content of machine-made charcoal is high, usually around 80%, and the calorific value is relatively high. Machine-made charcoal has a long burning time and lasting heat, which can meet the needs of long-term and high-intensity combustion.

4. Environmental protection: Machine-made charcoal burns without smoke and charcoal heads. During the combustion, the residual ash falls naturally without floating up, reducing dust pollution. In addition, because trees are not cut down, but bamboo and wood product waste is used for production, the damage to forest resources is reduced, which is conducive to the protection of the ecological environment.

5. Versatility: In addition to being used as fuel, machine-made charcoal can also be used for barbecue, smoking food, air purification, beauty and skin care, and many other purposes.

Biomass pyrolysis carbonization furnace

Biomass pyrolysis carbonization furnace

After a detailed introduction, I believe you have enough understanding of charcoal making. If you want to customize a set of suitable biomass pyrolysis carbonization furnace, Henan DOING will be your best choice. Our carbonization equipment has advanced structure and reliable operation. Contact us for solutions!

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.