WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How profitable is EV battery recycling and what materials can be recovered?

December 5, 2024

December 5, 2024- Industry News

- Leave a message

- Chat online

With the rapid expansion of the global electric vehicle market, the recycling of EV batteries has become increasingly prominent. EV batteries contain a large number of valuable metals. Recycling and processing these batteries is not only about resource reuse, but also conducive to environmental protection. So, how much profit can be made from recycling EV batteries? What materials can be recycled?

EV batteries

EV batteries

What materials can be recycled from EV batteries?

The recyclable materials in EV batteries, which is the main source of income for recycling lithium batteries, mainly include the following categories:

Metal materials:

1. Rare metals: such as lithium, cobalt, nickel and manganese, which are important components of battery positive electrode materials and have high refining value.

2. Conventional metals: such as copper, aluminum and iron, which mainly constitute the negative electrode, shell and connectors of the battery.

Non-metallic materials:

Plastic diaphragm: The diaphragm is located between the positive and negative electrodes of the lithium-ion battery and is one of the key inner components of the battery. It can also be reused or sold after recycling.

Materials can be recycled from EV batteries

Materials can be recycled from EV batteries

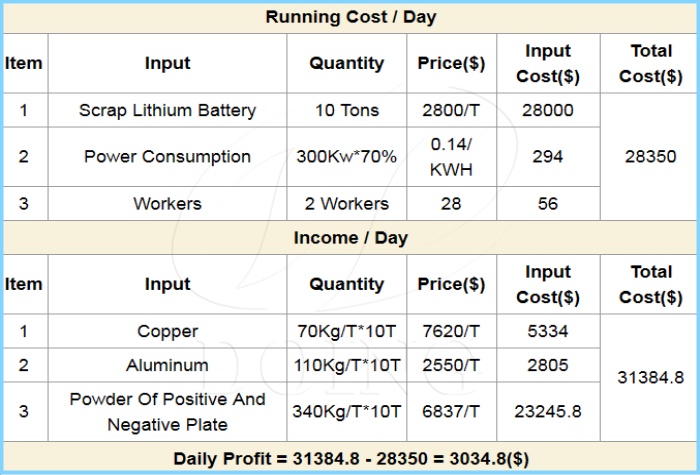

Profit analysis of EV battery recycling

1.Global electric vehicle sales continue to rise, and with it, a large number of batteries will enter the scrap period after a few years. As the scale of the battery recycling industry continues to expand, this will drive down recycling costs and increase profits. For example, during the recycling process, as the number of processed batteries increases, the unit transportation, disassembly and extraction costs will decrease. Large-scale recycling companies can achieve cost reduction and increase profit margins by optimizing processes.

2.Valuable materials extracted from EV batteries have a high value in the market. EV batteries, especially lithium-ion batteries, contain a large number of rare metals such as copper, aluminum, lithium, cobalt, nickel, etc. These metals are expensive in the market and have a high recycling value. For example, the market price of cobalt powder can reach $24 per kilogram, and lithium powder can reach $12 per kilogram. Therefore, recyclers can use professional technology to separate these substances from waste batteries, thereby making high profits.

3.In order to promote sustainable development and resource recycling, many countries and regions have introduced a series of policies to support battery recycling, including financial subsidies, tax incentives and priority procurement. For example, some local governments give battery recycling companies a certain amount of subsidies for each ton of batteries processed. This directly increases the company's income, and at the same time, tax incentives also help to reduce the burden on the company, thereby improving the company's profitability.

Profit analysis of EV battery recycling

Profit analysis of EV battery recycling

How to recycle EV batteries for high profits?

Recycling EV batteries is a difficult problem that requires advanced technology and recycling equipment. Efficiency and quality must be guaranteed, and the environment must not be polluted. The emergence of a new EV battery recycling machine developed by Henan DOING Company has solved this problem.

The new electric vehicle battery recycling machine designed by Henan Doing Company can classify and recycle useful materials in waste electric vehicle batteries through the mature recycling process, including discharge, crushing, screening, separation and other processes. The EV battery recycling machine adopts a multiple screening and separation system, and the product separation rate can reach 99%, ensuring the high investment payback.

Additionally, the entire electric vehicle battery recycling production line is equipped with professional negative pressure purification, black powder collection, deep purification and other processes and systems to ensure that no secondary pollution will be generated during the production process, ensuring the environmental protection of the recycling process.

EV battery recycling machine

EV battery recycling machine

The EV battery recycling machine can not only recycle EV batteries, but also handle laptop batteries, mobile phone batteries, energy batteries, cylindrical batteries, etc. The entire production line is controlled by a PLC system with a compact design and space saving. In addition, our equipment also uses a dry physical separation method and an environmentally friendly dust removal system, which is pollution-free and meets environmental protection requirements.

The profit margin of electric vehicle battery recycling is large, and the types of recyclable materials are rich. Driven by policies and continuous technological progress, the EV battery recycling industry will become an indispensable part of the future automotive industry chain. If you also want to make high profits by recycling EV batteries, you can consult us to customize a solution exclusively for you! For more relevant information about EV battery recycling machine, please pay attention to our website!

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.